The vacuum hopper loaders are widely used in the raw material transportation of injection molding machines, extruders and other equipment. It has the advantages of convenient installation, simple operation, strong long-distance transportation capacity, stable production and reliable operation. It is an auxiliary equipment for automatic production.

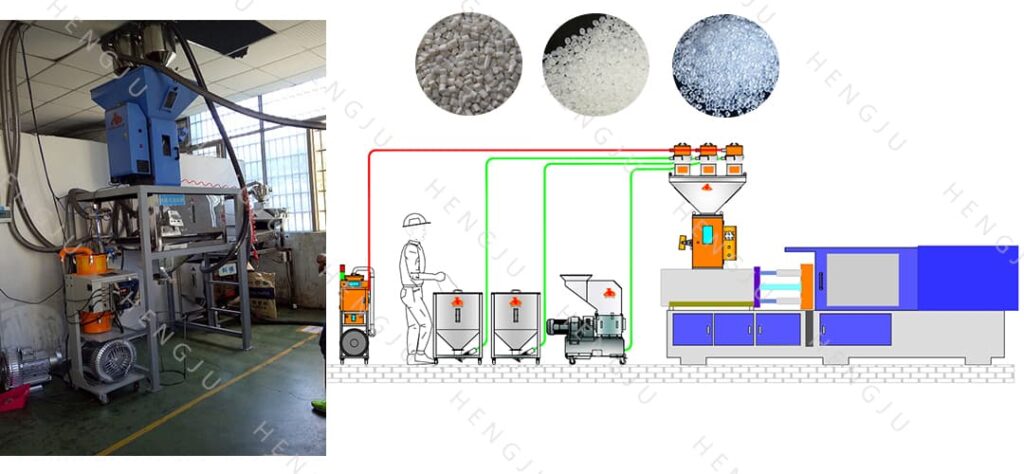

Working connection principle and structure

The auto loaders are used for raw material transportation, which can automatically feed the plastic auxiliary machine or injection molding machine. The plastic auto loader uses the principle of negative pressure to suck the plastic raw materials into the hopper from the suction port. When the material barrel of the plastic central feeding system is full, the switch valve of the material bin will output the material from the outlet through mechanical induction or photoelectric induction, and transport it to the plastic auxiliary molding equipment.The whole process is controlled by microcomputer, and the suction process is in a closed state, which reduces the leakage of dust, reduces labor costs, and improves production efficiency.

What industries and raw materials are the suction machines suitable for?

The plastic loader is widely used in the transportation of raw materials in food, plastic, film, chemical, pharmaceutical and other industries. The applicable raw materials mainly include PE, PP, PC, PA, POM, PS, etc. Powder and particles are suitable for pneumatic conveying by the suction machine , the raw material is relatively dry, not easy to be affected by moisture, and has no adhesion.

What should I do if the vacuum hopper loaders does not suck material?

1. Insufficient air supply pressure.

First start the vacuum pump manually to check whether the pressure gauge and air flow of the vacuum pump are normal. If the vacuum is too high, the conveying pipe of the suction machine may be blocked or leak.

When starting the vacuum pump, check whether there is suction at the suction port. If the suction is low, check whether the pipeline is tightly connected and in a sealed state, and whether the pipeline is damaged.

2. The sealing ring is worn out.

During the long-term use of the suction machine, the sealing ring will appear aging and wear, resulting in air leakage, less suction or no suction.

3. The discharge valve is stuck.

Observe whether the startup and shutdown state is stuck every time, if it is stuck and not closed properly, there will be a situation of less suction and no material suction.

4. Bad contactor.

Check whether the power contactor is broken and whether the capacitor of the machine is burned.

5. The filter screen is blocked.

Whether the filter element of the suction pipe is blocked by dust, the damaged filter screen dust is adsorbed on the internal parts of the machine, causing the suction machine to not suck material.

In addition to doing a good job of checking the related faults of the vacuum loader, the daily maintenance and regular maintenance of the vacuum loader are also very important.

Daily maintenance

1. Frequently clean the stainless steel filter screen of the hopper and the filter element of the main engine, regularly clean the dust material remaining in the filter to prevent clogging, and replace the damaged filter screen in time.

2. Check whether the power cord of the machine is worn, and whether the key functions of the control panel can be used.

3. Check whether the screws at the joints of the main body of the machine are loose or missing.

4. Check the sealing state of the connecting pipeline and each joint of the machine, and replace the damaged parts in time to ensure the sealing of the machine.

The hopper loaders is not a one-time product. The quality is determined by the technical level, production process, and accessories selection. Good products also need good follow-up services. Good manufacturers not only have excellent product quality, but also have guaranteed after-sales service.

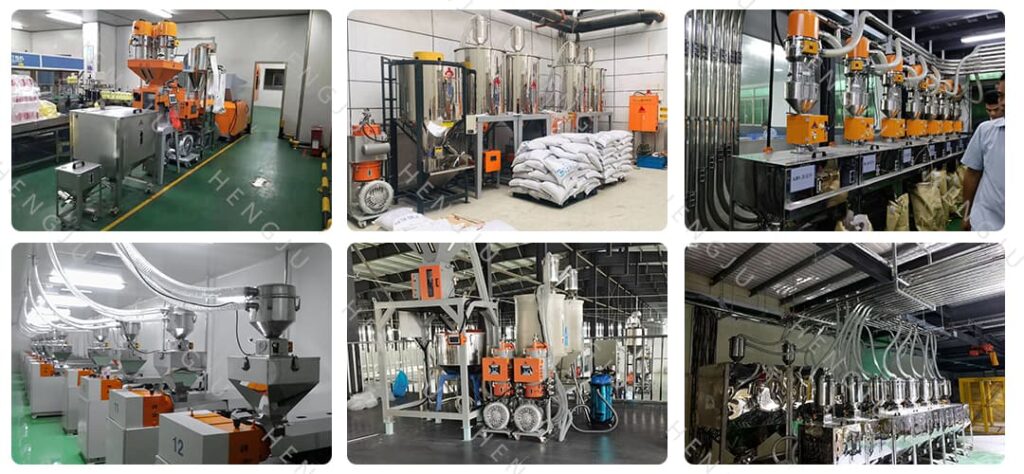

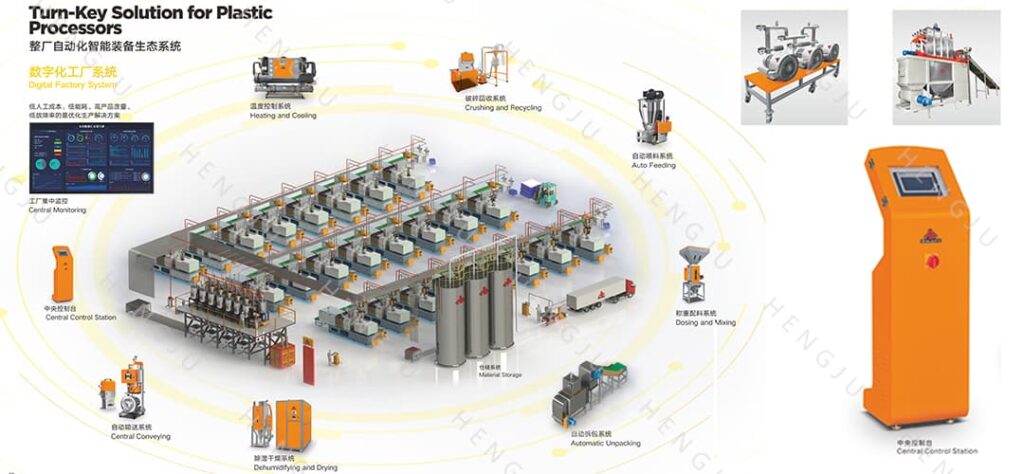

Since its establishment, Hengju Machinery has been focusing on the research and development of central feeding system, whole plant water and electricity planning, dehumidification and drying, and batching measurement, so as to make products closer to customer needs and customize perfect automation solutions for customers. It has provided stable and reliable intelligent systems for thousands of plastic manufacturers.

After years of development, Hengju people have been adhering to the tenet of “survive by quality and develop by reputation”, relying on strong professional technology and stable quality, we have won high comments from customers at home and abroad. Covering industries include auto parts, chemical industry, pelletizing, new energy, new materials, etc., and excellent performance in bio-degradable plastics such as PLA, PBAT, and pipe/sheet/cable extrusion and other fields!

We sincerely hope to work hand in hand with various plastic production industries and seek common development!