The controller of the central feeding system is easy to use and operate, and the central conveying system has functions such as modularization and central monitoring. At the same time, the industrial conveyor systems has scalability to achieve the supply of materials for the whole plant. For a long time, central conveyor system manufacturer have been the answer that investors and users want to know.

The dust collection bucket of the conveying solutions can filter and collect the dust generated during the raw material conveying process, so as to avoid the pollution of the workshop caused by flying dust. The selection of the dust collection bucket should mainly consider the convenience of cleaning.

The custom conveyor systems has the characteristics of high efficiency, energy saving, adjustability, and high degree of automation. Only a few people can control the auxiliary equipment of the entire workshop, realizing the all-weather operation of the conveyor system solutions. The conveyor transport system can also be used in conjunction with the dehumidification dryer to achieve perfect seamless integration technology.

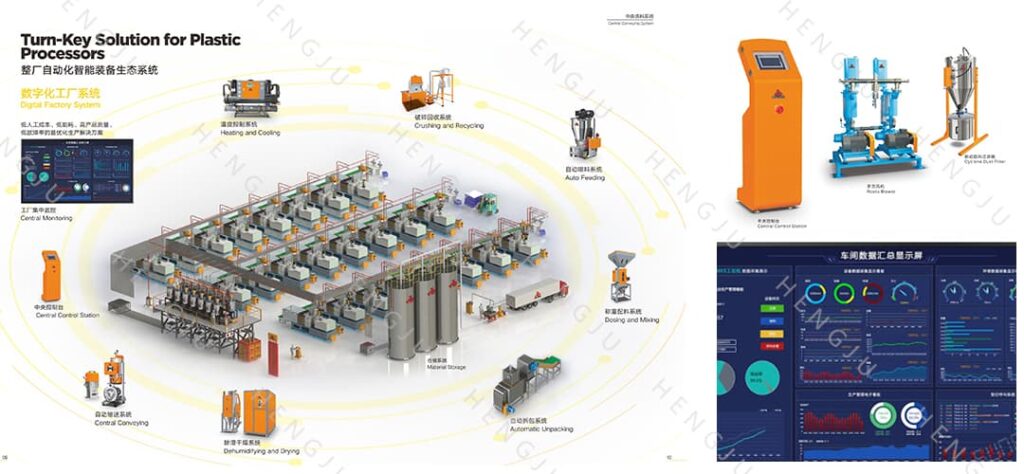

Hengju Machinery Equipment is a manufacturer specializing in the production of plastic peripheral auxiliary equipment; we can provide customers with plastic molding workshops to provide whole-factory design solutions; from workshop rough grain → raw material storage → raw material ratio measurement → crushing and recycling → dehumidification and drying → Transported to the molding machine to realize the application and management of the modern workshop.