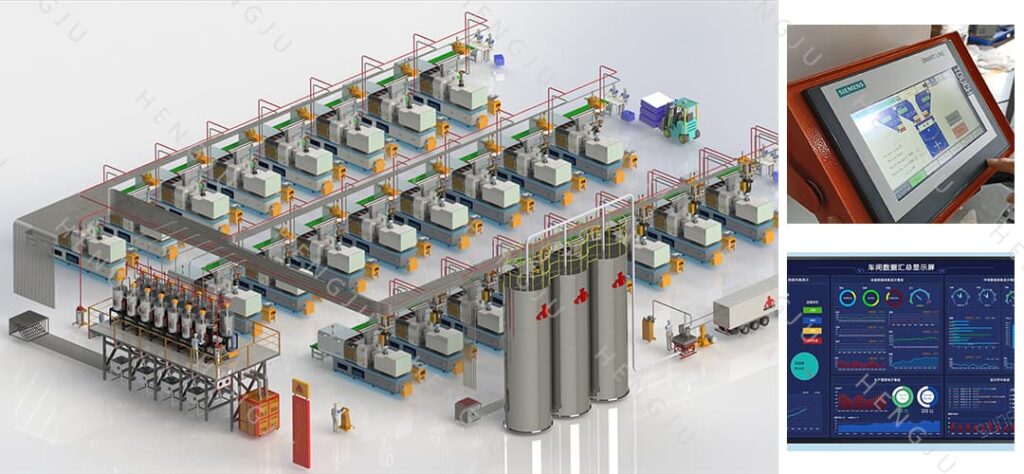

The characteristics of the central conveying system are briefly introduced as follows:

1.Humanized program control

Man-machine interface display, intuitive and simple operation, easy setting of working parameters, expandable central material conveying system, humanized program control makes system use and maintenance simple and clear, no need for professionals to use the system, we can experience technology personally resulting changes in production.

2.Centralized storage of raw materials

Centralized storage and management of raw materials, the raw material area and the molding area are completely separated, no drying equipment is used in the molding area, the molding operation space becomes larger, and the workers’ work is safer.

3.Concentrated use of drying equipment

Concentrate the use of drying equipment to minimize the number of drying cylinders, protect the working environment of the molding site, and reduce the energy consumption of drying equipment. Due to the isolation of the drying waste gas from the site, the temperature of the molding site is greatly reduced, and at the same time, the pollution and waste of raw materials scattered during raw material cleaning are reduced, and air pollution and dust pollution are completely improved.

The division of labor between the machine operator and the raw material administrator is clear, which is most suitable for the general company’s division of labor system and standardized management of employees.

4.Centralized Dust Recovery System

The unique centralized dust recovery system makes cleaning more convenient, and the environmental protection effect has leapt to a new level. The clean molding space can reduce the difficulty in handling the finished product due to electrostatic absorption of dust, and can improve product quality.

As a machinery and equipment industry, Hengju pays most attention to product quality, technology, service and price. The operation of the central automatic feeding system is to allow the materials to be automatically conveyed during the conveying process to achieve high production and high efficiency. In the transportation of food and pharmaceutical industries, the demand for large-scale standard centralized feeding system equipment will increase, and the demand for functional equipment combined with it will also increase. Highly automated conveying equipment will be welcomed in some applications!