The central feeding system, which called central conveying system is composed of the central console, cyclone dust collector, high-efficiency filter, fan, material selection rack, branch station, drying hopper, dehumidifier, micro-moving hopper, electric eye hopper, cut-off valve, air cut-off valve, etc. composed of various parts.

The components of the automatic feeding system are: the power part, also called the vacuum station; the dust removal device part, which generally adopts the combination of double dust removal to automatically remove dust; the raw material distribution station, also called the material selection station; the suction barrel, also called the suction hopper , Divided into vacuum and electric eye hoppers, conveying pipelines, vacuum pipelines, central consoles, and protection devices.

Different characteristics

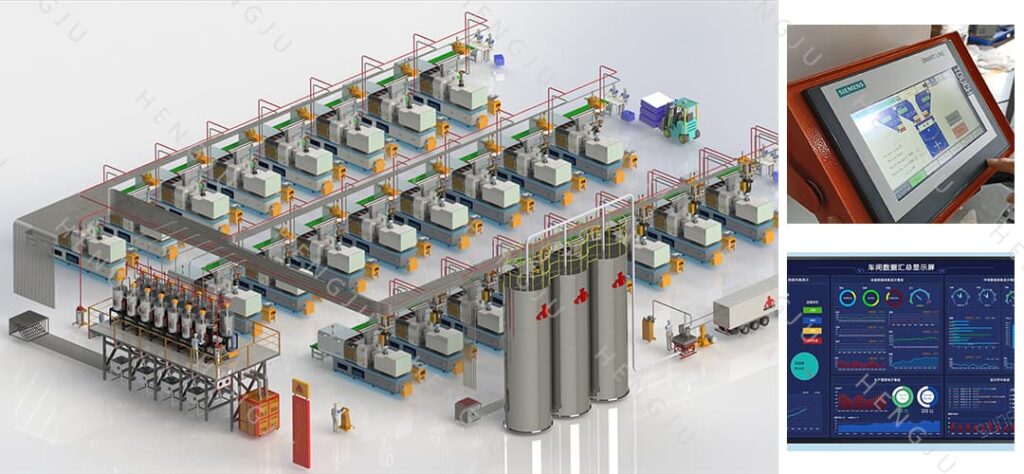

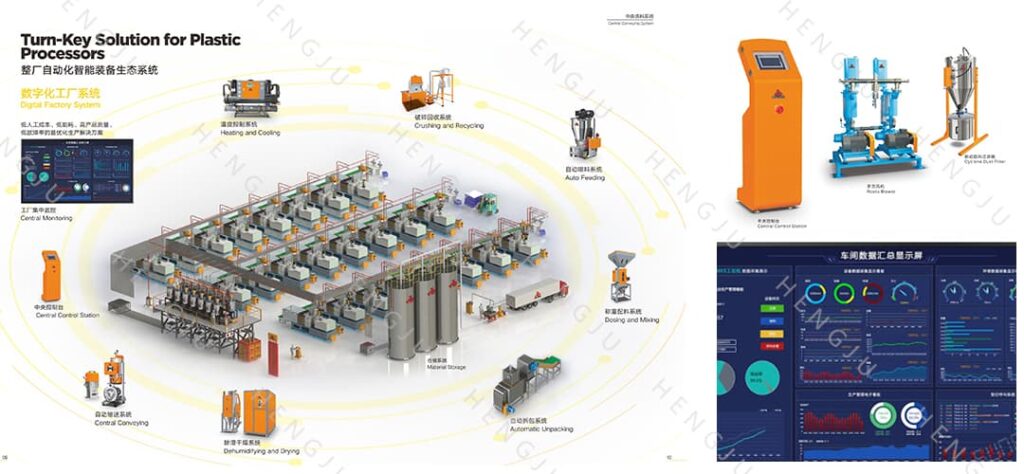

The central feeding system can realize the automatic supply of various raw materials to any injection molding processing equipment in multiple chambers, which can include the drying treatment of raw materials, color matching treatment, and the utilization of crushed recycled materials in proportion, which can implement a high degree of automatic control, Monitoring, etc., and can meet the 24-hour non-stop production needs. At the same time, the central feeding system is easy to operate, and only a few people can control the feeding demand of the entire injection molding factory, thereby reducing a lot of labor costs. It can meet different users, different workshop characteristics, and different raw material usage requirements. The optimal solution can be designed according to the actual needs.

The use of automatic feeding system can ensure the stable operation of the whole system, and there will be no phenomenon of plastic resurgence and material blocking. It is used in conjunction with the dehumidification and drying system to make the dry air dry the raw materials again to prevent the dried plastic from regaining moisture. At the same time, the conveying pipe is cleaned after each conveying cycle to ensure that there is no residual material in the pipe. While avoiding moisture regain of raw materials, it also ensures the consistency of raw materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in raw materials is filtered out through the filter (dust collector) system, which is beneficial to improve product quality.

Hengju is an integrated integrator focusing on the R&D and production of plastic molding auxiliary equipment and the design of the whole plant automation system. Years of industry experience has made Hengju always ahead of the same industry in China, and has a broad domestic and foreign markets. With the continuous development and expansion of overseas markets, Hengju’s product sales network has been distributed to dozens of countries in Europe, America, the Middle East, and Asia Pacific. The brand of Hengju is being accepted and recognized by more and more countries.