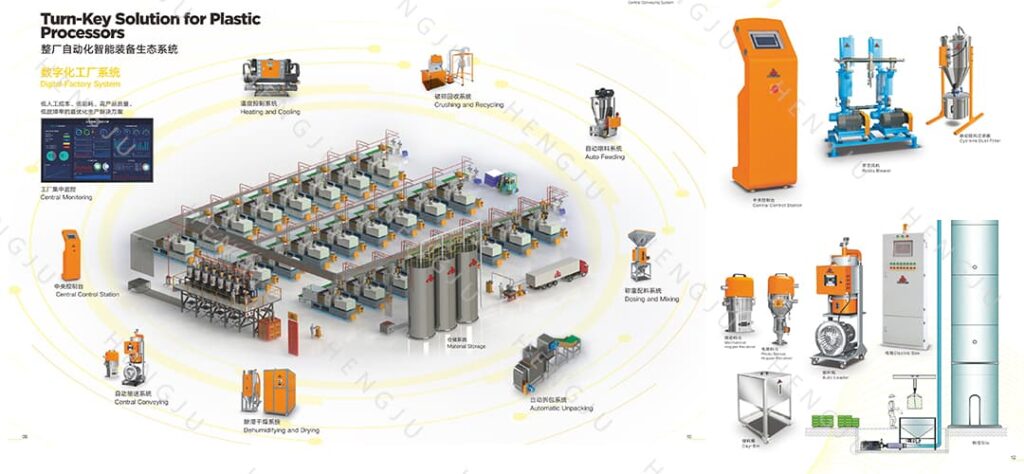

The central conveying system is a centralized production system serving plastic production, and the growing industry technology development and market demand drive the development of central conveying.

1.Automatic operation to improve production efficiency

The central conveying system breaks the time limit and realizes 24-hour continuous and uninterrupted production in the injection molding workshop.

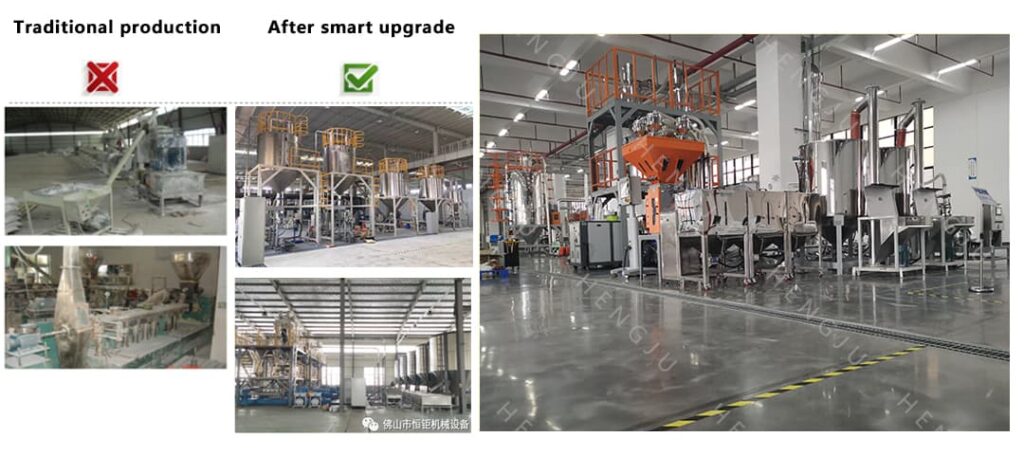

The production process is digitized, and various production processes can be monitored in real time. The centralized transportation management of raw materials, drying treatment, weighing and color matching treatment, and the utilization and treatment of defective crushed and recycled materials have all realized automatic operations, effectively improving the production efficiency of the workshop.

2.Concentrated transportation of raw materials, saving time and labor

The central conveying system adopts centralized automatic unpacking and conveying, stores the raw materials in large outdoor or indoor silos, and then uses vacuum transmission to transport the plastic raw materials to the central dehumidification and drying system through a centralized pipeline system, and finally the dried Raw materials are transported to the main machine for production.

This method reduces manual participation, and the automatic unpacking and conveying system is more efficient than traditional manual conveying, saving time and effort.

3 Reduce costs and increase efficiency to enhance the competitiveness of enterprises

The central conveying system is easy to operate, and a small number of personnel can control the supply demand of the entire workshop, reducing the large demand for personnel in the injection molding workshop and reducing the labor cost of the enterprise.

The central conveying system centralizes storage, transportation, dehumidification and drying, which greatly improves the utilization of space. At the same time, replacing multiple small dryers with one large dryer with the same output will reduce a lot of auxiliary stand-alone equipment, thereby saving electricity and equipment maintenance costs.

The equipment is placed in a centralized manner, and the pipelines for the central supply are arranged in an orderly manner to make the workshop environment tidy and enhance the corporate image.

For Hengju people, through their own hard work and learned skills, they become the mainstay of the company, and employees can be proud of working in Hengju. For Hengju, high-quality talents are the most important resources of the company. The overall growth of the team is the core of Hengju and the driver of all customer-centric concepts.