Stop Losing $42,000/year

on Plastic Material Waste

How home appliance factories cut molding scrap rate by 67% with our closed conveying system

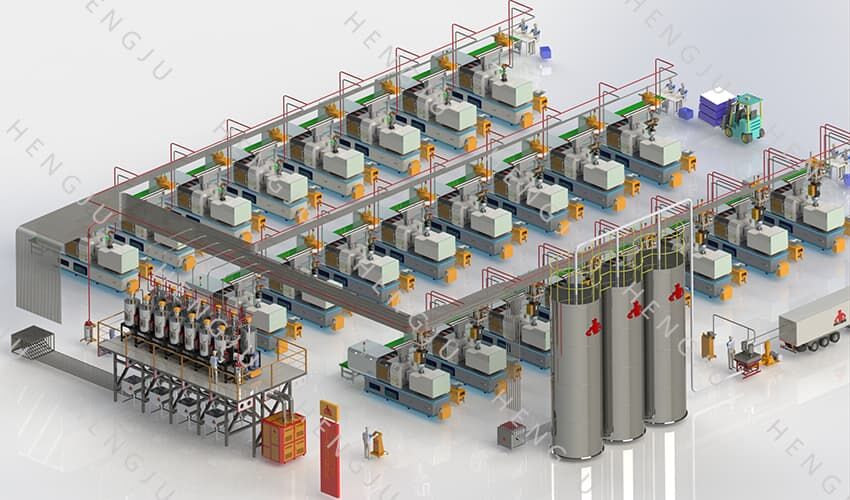

Central Feeding System For Home Appliance Injection Molding Workshop

The injection molding industry relies heavily on efficient material handling system, and a centralized feeding system is a key component in achieving this. A central conveying system is essential for ensuring a steady and consistent flow of material to the molding machine, as well as reducing material waste and minimizing downtime due to material handling issues. With a central feeding system, plastic resin pellets can be automatically transported from a storage area to multiple molding machines, increasing efficiency and productivity.

Complete Vacuum Conveying

A fully enclosed system that minimizes material loss and prevents dust contamination.

Calculate Your Potential Savings

Estimated Annual Savings:

$0

*Based on industry average savings of $84/ton