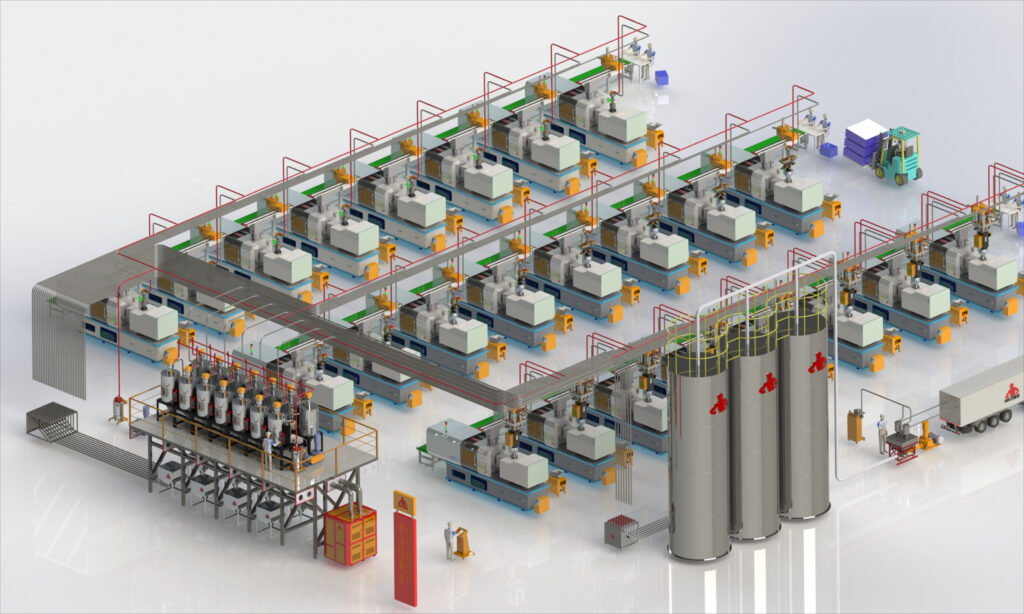

A central conveying system is a type of material handling system used to move bulk materials

,such as powders or pellets, from one location to another in a manufacturing or processing facility. The working principle of a central conveying system involves several key components that work together to transport materials efficiently and safely:

- Material source: The central conveying system begins with a material source, which could be a storage bin, silo, or other container where the bulk material is stored.

- Conveying pipeline: A network of pipes, typically made of plastic or stainless steel, is used to transport the material from the source to the destination.

- Vacuum pump: A vacuum pump is used to create suction within the pipeline, which pulls the material through central conveying system.

- Material receiver: At the end of the pipeline, a material receiver or hopper collects the material and prepares it for use or further processing.

- Control system: A control system monitors and regulates the flow of material through the system, ensuring that it moves at the appropriate speed and volume.

Overall, the central conveying system works by using the vacuum pump to create a pressure differential that moves the material through the pipeline. The control system ensures that the material moves smoothly and efficiently, while the material receiver collects the material at the end of the line. This system is ideal for moving large volumes of bulk material over long distances, with minimal manual intervention.

Since its establishment, Hengju has been focusing on the research and development of dehumidifying & drying, dosing & mixing and central conveying systems to make products closer to customer’s demand and customize complete automation solutions for customers.