The central feeding system helps to improve the thermoforming process

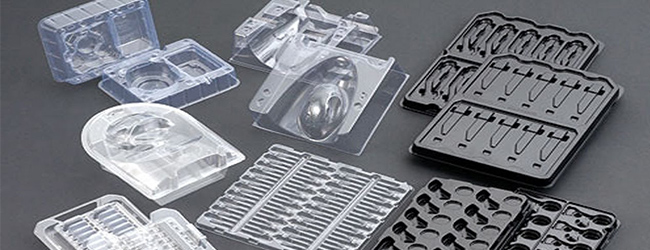

At present, thermoforming is already one of the most important processing and forming methods in the plastic processing industry, and the application of thermoformed plastic products in my country is gradually increasing. Compared with other processing technologies, thermoforming has the characteristics of wide range of applicable materials, flexible processing and application, and high production efficiency. However, there are many shortcomings in the development of thermoforming technology in my country. The typical performances are: compared with foreign countries, my country’s thermoforming machine technology still lags behind. There are obvious gaps, the technological innovation ability of thermoforming enterprises is poor, and there are many small and medium-sized thermoforming enterprises. These factors are affecting the further development of thermoforming technology.

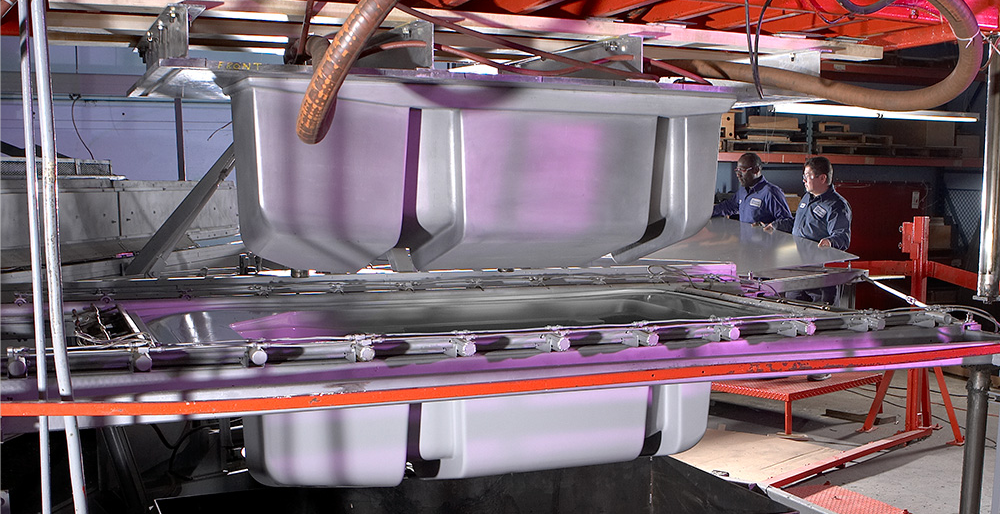

However, in recent years, with the continuous improvement of labor costs in my country’s market and the requirements for processing efficiency and quality stability, enterprises in my country’s thermoforming industry chain have significantly accelerated the pace of technological innovation. Thermoforming equipment has also begun to gradually get rid of the previous only as an independent plastic sheet forming system, and began to combine with other production equipment to form a complete production line that meets specific needs, thereby further improving production efficiency and reducing the cost of the final product. Cost of production. In particular, the application of the central feeding system has greatly improved and perfected the relevant processes, making the thermoforming industry show a trend of vigorous development.

It is understood that plastic thermoforming equipment is divided into manual, semi-automatic and fully automatic according to the operation mode; according to the feeding method, there are batch feeding and continuous feeding. As a central feeding system for the rationalization of plastics processing, it has become an indispensable part of the automation of thermoforming plastics processing. First of all, the central feeding system adopts PLC technology, which can realize production automation, and the operation is simple and convenient. The operator can control the central feeding system after simple training. From raw materials→storage→measurement→transportation→use, there are special accessories that can be applied in different production environments. Secondly, the central feeding system can realize a high degree of automatic control, monitoring, etc., and can meet the production needs of 24 hours non-stop, which improves the production efficiency. Furthermore, the central feeding system can centrally manage raw materials, and fans and crushers are installed in isolation, which can not only improve the utilization rate of space, but also reduce dust pollution and create a comfortable production environment.

Hengju Machinery has been serving customers with high-quality technology and services. For many years, it has focused on large-scale plastic industry material transportation projects, plastic manufacturing industry centralized feeding system projects, and plastic unmanned workshops. Design and automation auxiliary equipment provide comprehensive and professional solutions.