Why Are Plastic Products Easily Broken When Demoulding?

In the injection molding industry, we are faced with a common and troublesome problem: plastic products are broken when they are demoulded, which has brought great trouble to our production. Whether it is a design defect or a material problem during the production process, the breakage of plastic products will lead to low production efficiency, reduced product quality, and even unnecessary losses.

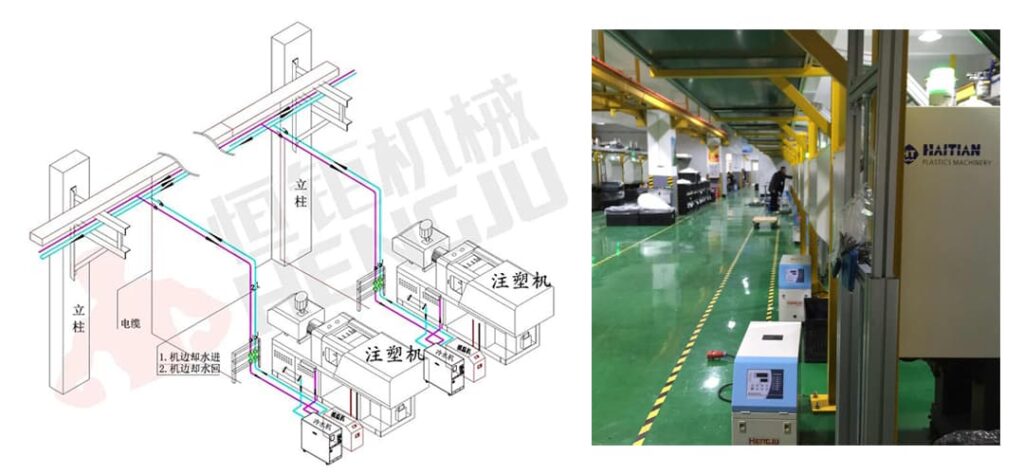

However, we have a key solution – the injection molding mold temperature controller. It is an essential equipment in the injection molding industry and can help us solve the problem of demoulding and breaking.

The mold temperature controller ensures that the plastic reaches the proper temperature during the injection molding process by precisely controlling the temperature of the mold. This can not only avoid the breakage of plastic products during demoulding, but also improve production efficiency and product quality.

The mold temperature controller has the advantages and functions of automatic adjustment and compensation, accurate measurement, rapid heating and cooling, etc. It can help us accurately control the temperature, avoid over-injection and plastic spillage, reduce demoulding breakage rate, and improve production efficiency and product quality.

Many injection molding companies have adopted mold temperature controllers and achieved success. They reduced the demoulding breakage rate, increased production efficiency, and customers were more satisfied with the quality of the products.