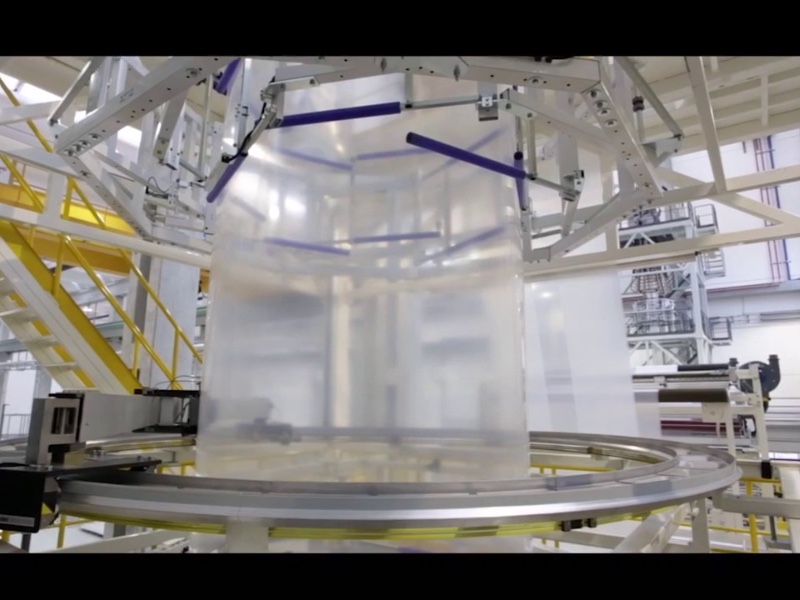

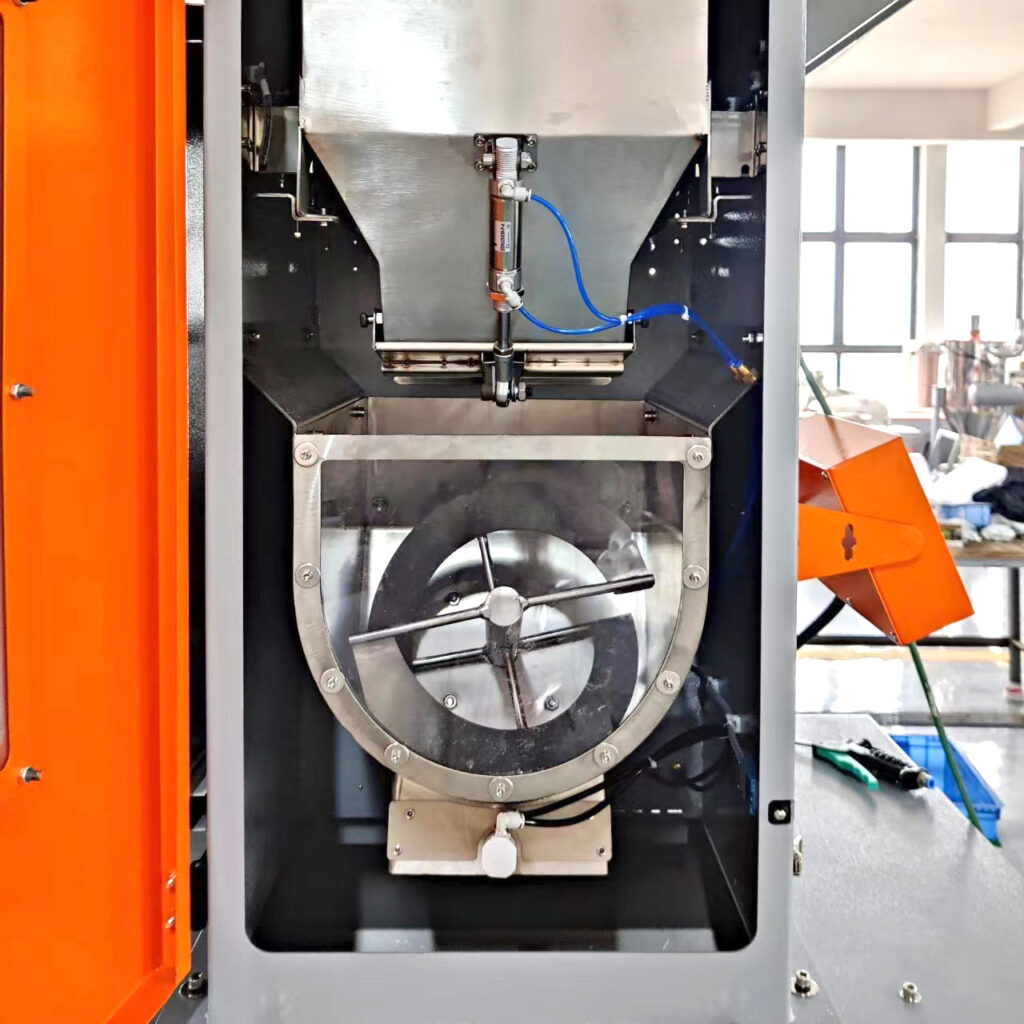

In the ever-evolving landscape of the blown film industry, technological advancements play a pivotal role in enhancing efficiency and product quality. One such groundbreaking innovation making waves in the sector is the Gravimetric Batch Blender, a sophisticated and automated system that has redefined the way materials are mixed and processed in film extrusion.

Gravimetric Batch Blenders: A Paradigm Shift:

Traditionally, manual blending processes in the blown film industry were time-consuming and susceptible to human error. Enter the Gravimetric Batch Blender, a cutting-edge solution that has revolutionized the landscape by automating and optimizing the blending process. This state-of-the-art technology ensures precision and consistency in material ratios, eliminating variations that could compromise the quality of the end product.

Enhanced Efficiency and Cost Savings:

The implementation of Gravimetric Batch Blenders has ushered in a new era of efficiency for manufacturers in the blown film industry. By automating the blending process, companies can achieve higher production rates while maintaining stringent quality standards. The elimination of manual errors not only enhances the overall product quality but also significantly reduces material wastage, leading to substantial cost savings for businesses.

Accurate Material Proportioning:

At the heart of the Gravimetric Batch Blender is its ability to provide accurate material proportioning. This ensures that the desired mix of raw materials is consistently achieved, resulting in films with precise specifications and characteristics. The precision offered by these automated systems contributes to the production of high-performance films that meet the stringent requirements of various industries.

Real-time Monitoring and Control:

Gravimetric Batch Blenders come equipped with advanced monitoring and control features, allowing operators to oversee the blending process in real-time. This level of control empowers manufacturers to make immediate adjustments if deviations from the desired blend ratios are detected. The result is a more agile and responsive production process that adapts to changing requirements with ease.

Quality Assurance and Compliance:

In an industry where product quality is paramount, Gravimetric Batch Blenders serve as a reliable tool for ensuring consistency and meeting regulatory standards. The automated nature of the blending process reduces the likelihood of human errors, contributing to a higher level of quality assurance. This, in turn, helps manufacturers build trust with customers and ensures compliance with industry regulations.

Conclusion:

As the blown film industry continues to embrace technological advancements, Gravimetric Batch Blenders stand out as a game-changer. Their impact on efficiency, cost savings, material proportioning, real-time monitoring, and quality assurance cannot be overstated. Manufacturers adopting this cutting-edge technology position themselves at the forefront of innovation, setting new benchmarks for excellence in film extrusion. The Gravimetric Batch Blender has indeed become a cornerstone in shaping the future of the blown film industry.

If you want to know more about plastic auxiliary machines, please subscribe to Xiaojuren’s YouTube account