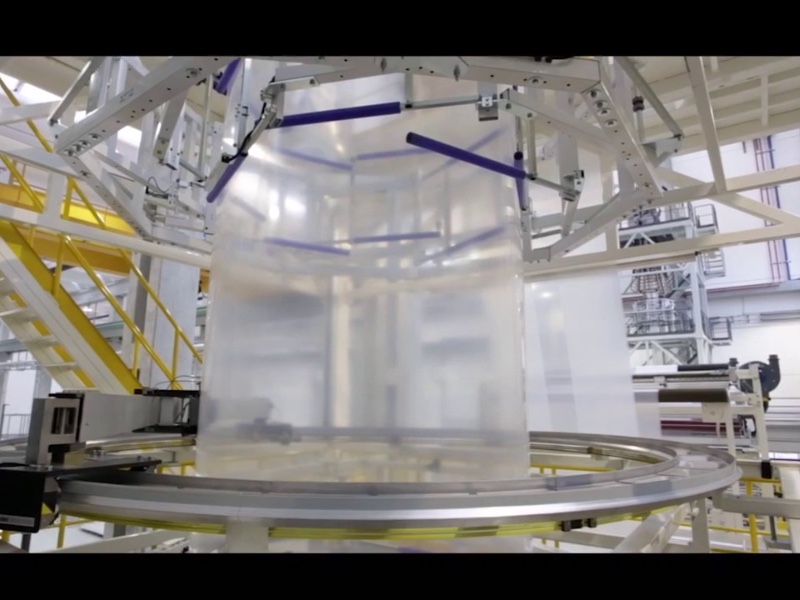

In the blown film industry, gravimetric blenders play a crucial role by precisely controlling and mixing multiple materials to ensure product quality and production efficiency. Here are the specific functions of gravimetric blenders in the blown film industry:

- Accurate Blending: Gravimetric blenders can accurately measure and mix different types of plastic pellets and additives, such as color masterbatches and stabilizers. This precision ensures consistency in every batch, thereby guaranteeing the quality and performance of the blown film.

- Increased Production Efficiency: Gravimetric blenders enable automated and continuous operation, reducing the need for manual intervention and minimizing the likelihood of errors. This not only boosts production efficiency but also reduces fluctuations and uncertainties caused by manual operations.

- Improved Product Quality: Through precise blending and mixing, gravimetric blenders ensure that each batch of material has a consistent composition, which is critical for producing high-quality films. Uniform material mixing can enhance the film’s mechanical properties, transparency, and color uniformity.

- Reduced Waste and Cost: Due to the high precision and automation of gravimetric blenders, material waste is significantly reduced. Additionally, they can optimize material usage, lowering production costs.

- Data Tracking and Management: Modern gravimetric blenders are often equipped with data recording and tracking functions, which can document specific information for each blend. This aids in production management and quality control, allowing for the timely identification and resolution of production issues.

- Adaptability to Various Materials: The blown film process may require different types of polymers and additives. The flexibility of gravimetric blenders allows them to handle a variety of materials, meeting diverse production needs.

In summary, the application of gravimetric blenders in the blown film industry can significantly enhance the automation and precision of the production process, ensure product quality consistency, reduce production costs, and improve overall production efficiency.

More automatic proportioning and metering equipment>>>>