Introduction

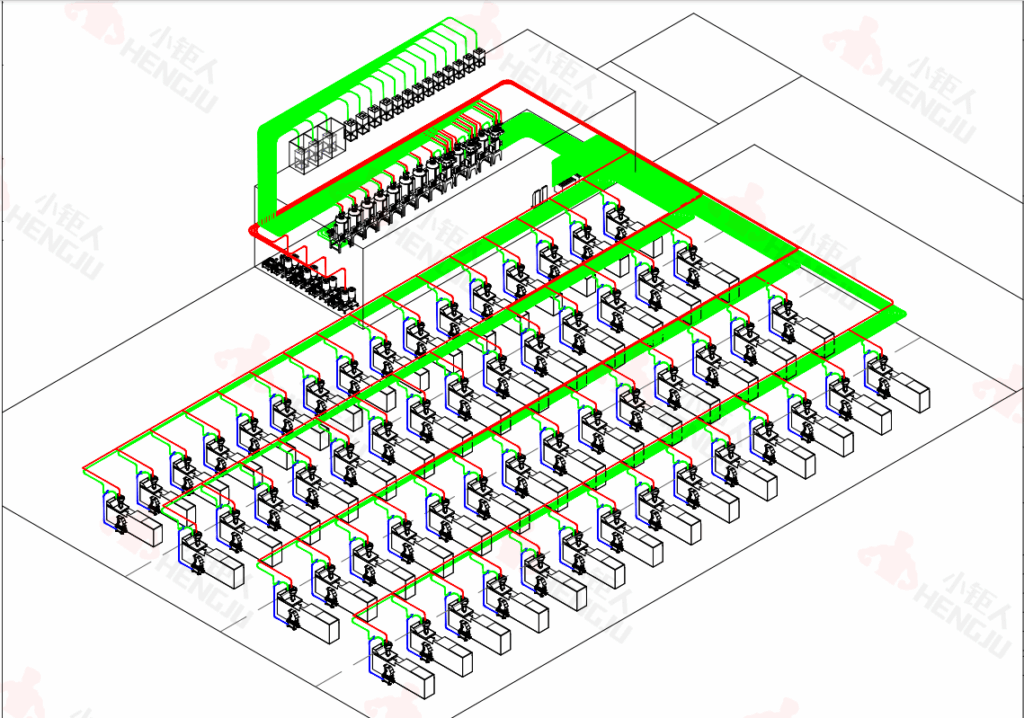

Injection molding plants today face intense pressure to increase output, reduce costs, and maintain a clean, efficient environment. If you’re looking to improve production efficiency, reduce material waste, and streamline operations in your injection molding factory, understanding the central feeding system benefits is essential.

In this article, we explore the top 5 reasons why injection molding plants are upgrading to centralized feeding solutions.

Benefit #1: Cut Labor Costs by Centralizing Material Handling

Traditionally, each injection molding machine requires a worker to monitor and refill materials manually. This leads to high labor intensity and human error.

A central feeding system changes everything:

- One operator can manage raw material supply for 10–30 machines

- Less manual work, fewer mistakes, and lower staffing costs

💡 Tip: Some customers reported that they saved up to 70% of labor costs by installing a central feeding system.

Benefit #2: Boost Production Efficiency and Reduce Downtime

Manual feeding often causes unexpected machine stoppages due to material shortages. Central feeding solves this by:

- Automatically delivering materials on demand

- Maintaining a continuous production flow

- Avoiding delays and production interruptions

You get smoother operations and better machine utilization.

Benefit #3: Reduce Raw Material Waste and Improve Accuracy

Material waste is money lost. Central feeding systems are designed to:

- Prevent overfilling and spillage

- Reduce handling errors

- Keep dosing and mixing precise (especially when combined with gravimetric blenders)

✅ The closed conveying system can also prevent raw materials from moisture and contamination, ensuring product quality from the source.

Benefit #4: Keep Your Workshop Clean and Organized

A clean factory isn’t just about appearance — it affects safety, efficiency, and product quality.

Central feeding systems create:

- Fewer open bags and hoses around machines

- Less dust and floor contamination

- Cleaner pathways and safer workspaces

Your workshop becomes more professional, and cleaning time is greatly reduced.

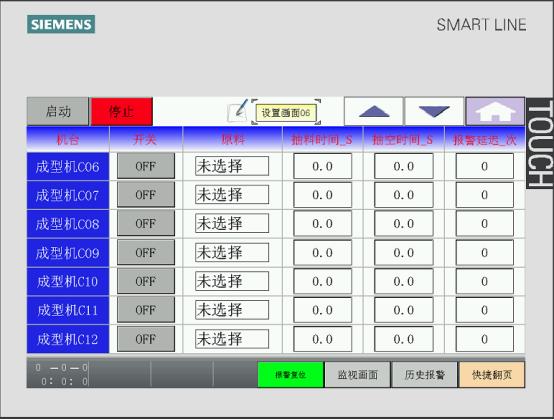

Benefit #5: Easy Control, Maintenance, and Future Expansion

Everything is connected to one central control system. You can:

- Monitor material use and supply status in real time

- Quickly locate and solve issues

- Expand the system easily when adding new machines

🌟Whether you have 5 machines or 50 machines, you can achieve flexible expansion and one system can solve all feeding problems.

Conclusion

Investing in a central feeding system is one of the smartest moves an injection molding plant can make. It not only improves production and reduces waste but also creates a cleaner, more organized, and future-ready workspace.

Less labor. More efficiency. Zero waste. Cleaner workshop.

👉Learn more about how central feeding systems work and whether they’re right for your factory. Read the full guide here.

👉 Looking to upgrade your injection molding process?

Contact us for a free consultation and system layout design!

Ready to upgrade your material feeding system?

✉Request a Free Layout Plan

📋 Download Technical Brochure

Contact now

Email: Jenny@gdhengju.com