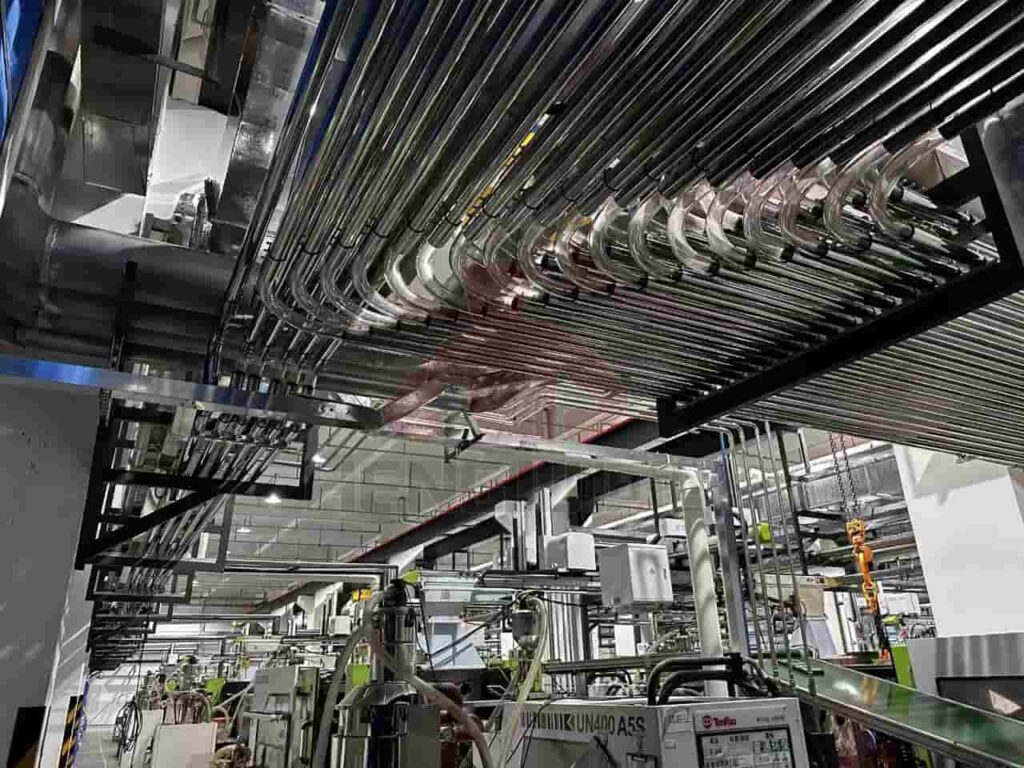

Central Feeding System for PET Sheet Extrusion Lines: A High-Output Case Study

Industry Background: PET Sheet Extrusion and Material Handling Challenges PET sheet extrusion is widely used in food packaging, thermoforming, and industrial applications.Compared with injection molding, PET sheet extrusion lines typically operate continuously, with high and stable material consumption, often exceeding hundreds of kilograms per hour per line. For PET processors, material stability, clean handling, and […]

Central Feeding System for PET Sheet Extrusion Lines: A High-Output Case Study Read More »