During economic downturns, the plastics manufacturing industry faces challenges in cost reduction and efficiency enhancement, necessitating practical measures for addressing these issues. Utilizing plastic auxiliary equipment is a crucial method that can help companies reduce costs and improve efficiency during production processes.

About Guangdong Xiaojuren Machinery Co., Ltd.

Established in 2008, Guangdong Xiaojuren Machinery Co., Ltd. is a professional manufacturer of plastic auxiliary equipment with 14 years of experience in production and research and development. We boast an experienced sales and R&D team dedicated to providing high-quality and efficient plastic production solutions. Our product range includes automated injection molding machines, extruders, molds, and other plastic auxiliary equipment.

In the challenging economic environment, our products from Guangdong Xiaojuren Machinery Co., Ltd. are exported to 81 countries and regions worldwide, earning widespread recognition and trust. Our equipment and solutions help customers reduce costs, improve production efficiency, and maintain competitiveness in the fiercely competitive market.

Here are several ways in which the plastics manufacturing industry can achieve cost reduction and efficiency improvement through plastic auxiliary equipment during economic downturns, with Guangdong Xiaojuren Machinery Co., Ltd. being a leading supplier of these advanced solutions:

- Automated Production Lines: Introducing automated injection molding and extrusion machines from Guangdong Xiaojuren Machinery Co., Ltd. can significantly increase production efficiency and reduce labor costs. These advanced machines not only provide high-precision production capabilities but also lower scrap rates, saving on raw material costs.

- Energy-Saving and Environmentally Friendly Equipment: Our equipment from Guangdong Xiaojuren Machinery Co., Ltd. features energy-saving and environmentally friendly characteristics, employing advanced energy-saving technologies and materials to reduce energy consumption and production costs, while also meeting environmental requirements.

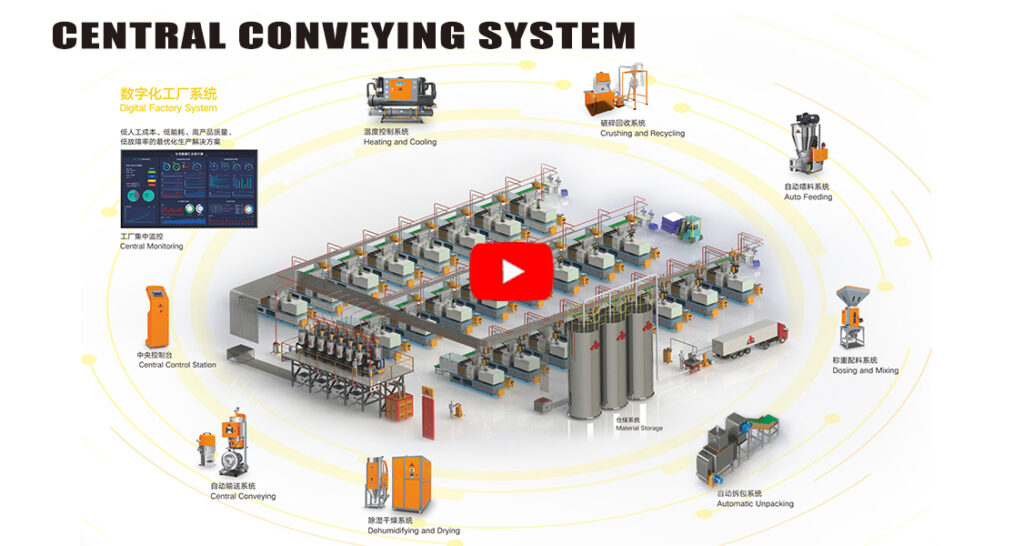

- Data Monitoring and Analysis Systems: The plastic auxiliary equipment from Guangdong Xiaojuren Machinery Co., Ltd. comes equipped with intelligent data monitoring and analysis systems that can monitor production processes in real-time and optimize workflows. These systems help reduce downtime and optimize raw material usage, thereby lowering production costs.

- Customized Production: Guangdong Xiaojuren Machinery Co., Ltd. offers customized plastic production equipment designed according to customer requirements, avoiding resource wastage and surplus, while improving production efficiency and flexibility.

- Technical Support and Training: As an industry leader, Guangdong Xiaojuren Machinery Co., Ltd. provides professional pre-sales consultation and after-sales service, including equipment operation training and technical support, to help customers fully utilize equipment advantages, reduce maintenance costs, and production risks.

By collaborating with Guangdong Xiaojuren Machinery Co., Ltd., companies in the plastics manufacturing industry can effectively tackle the challenges posed by economic downturns, achieve cost reduction, enhance efficiency, and contribute to the sustainable development of the industry.

Dehumidifying & Drying>>>

Dosing & Mixing>>>

Feeding & Conveying>>>

Granulating & Recycling>>>

Heating & Cooling>>>

Silos & Central conveying System>>>

Central Cold Water System>>>

Practical application cases of weighing and measuring equipment>>>