How to Choose the Right Material Conveying Method for Your Injection Molding Plant

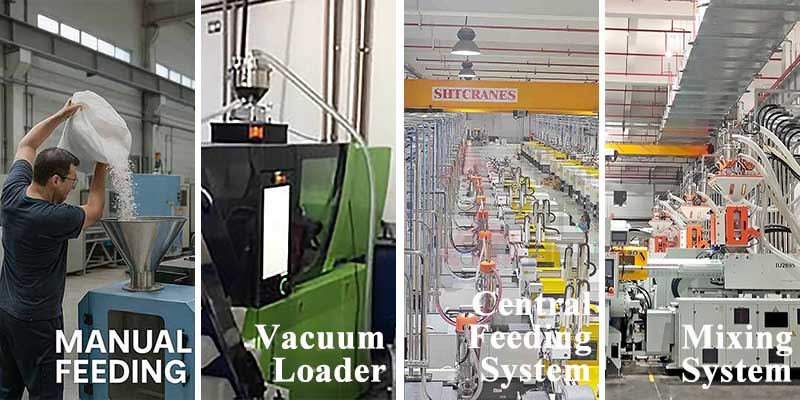

In injection molding factories, how raw materials are transported from storage to machines can significantly impact production efficiency, energy consumption, and operational cost. Whether you’re running a small workshop or a factory with 100+ machines, choosing the right material conveying method is a critical decision. In this article, we compare the most common conveying methods […]

How to Choose the Right Material Conveying Method for Your Injection Molding Plant Read More »