Central Feeding System for Blow Molding: Design, Benefits & Cost

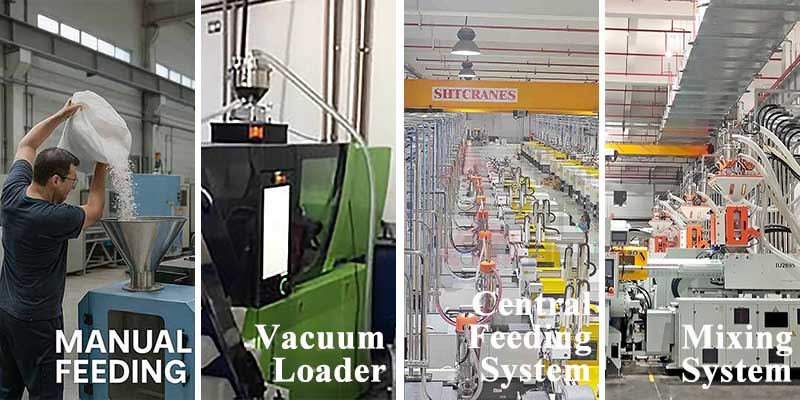

1. Introduction Blow molding factories often face challenges like inconsistent material supply, high labor costs, and dust contamination. A central feeding system for blow molding solves these problems by delivering raw materials directly from storage silos to each blow molding machine automatically. 2. How a Central Feeding System Works in Blow Molding 3. Benefits for […]

Central Feeding System for Blow Molding: Design, Benefits & Cost Read More »