How a Pipe Fittings Injection Molding Plant Optimized Material Flow Across 82 Machines?

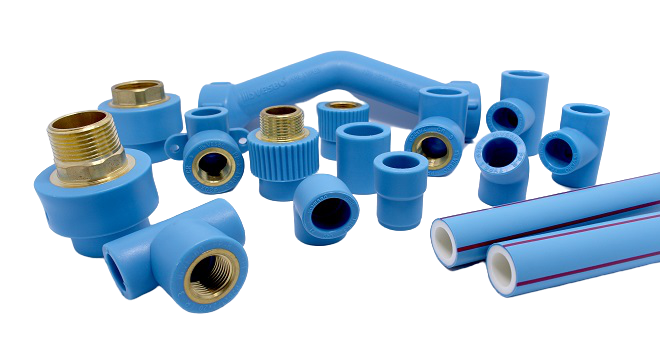

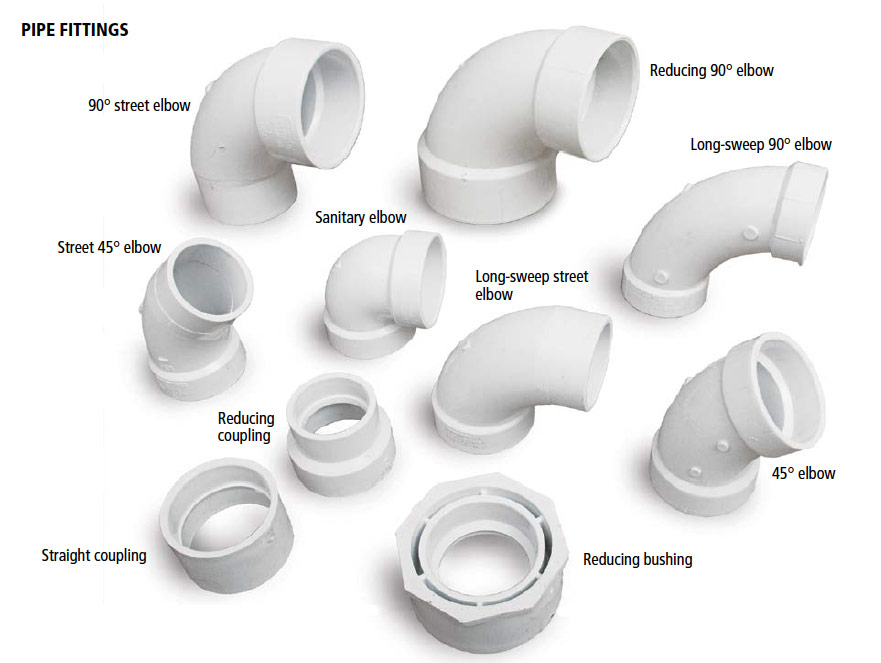

Large pipe fittings manufacturers face a unique challenge in injection molding production: high output, multiple material types, and continuous operation across dozens of machines.

In 2023, we completed a central feeding system project for an injection molding workshop belonging to one of China’s leading piping groups, primarily producing PPR and PVC pipe fittings.

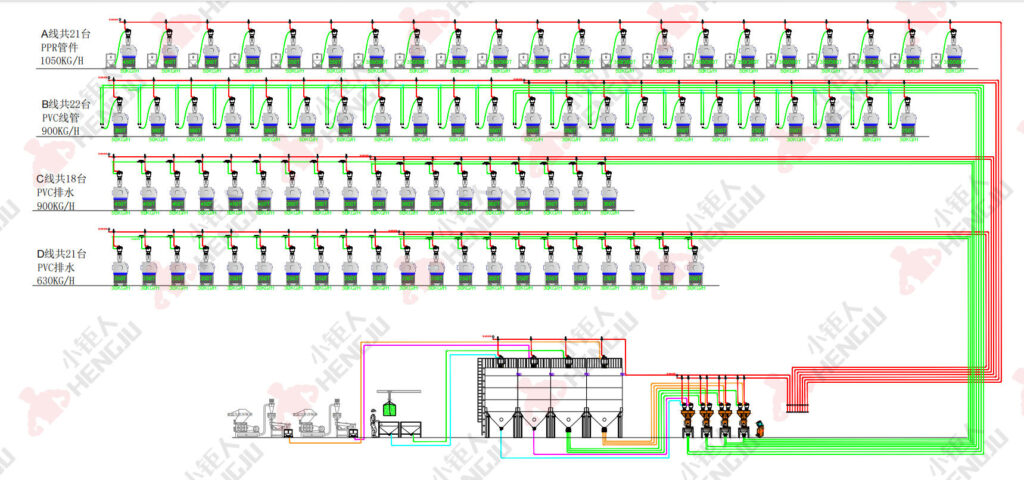

The project covered 82 injection molding machines across four production lines, with total material consumption exceeding 3,400 kg per hour. To ensure stable production, reduce manual handling, and maintain consistent material quality, a fully centralized material handling solution was required.

Understanding the Production Layout and Material Demand

The workshop operates four independent injection molding lines, each dedicated to different pipe fitting products:

- Line 1:

21 injection molding machines producing PPR pipe fittings, with a total output of 1,050 kg/hour - Line 2:

22 machines producing PVC electrical conduit, with a total output of 900 kg/hour - Line 3:

18 machines producing PVC drainage fittings, with a total output of 900 kg/hour - Line 4:

21 machines producing PVC drainage fittings, with a total output of 630 kg/hour

Different machine tonnages consume material at different rates, ranging from 30 to 50 kg per hour per machine, making precise and stable material delivery essential for uninterrupted operation.

Material Types and the Need for Controlled Handling

The factory processes four types of materials on a daily basis:

- Red virgin pellets

- White virgin pellets

- Red regrind material

- White regrind material

The customer already operated granulators with an integrated recycling system, so material reprocessing was handled internally. Our focus was on centralized storage, conveying, and accurate dosing—ensuring that recycled and virgin materials could be used reliably without affecting product quality.

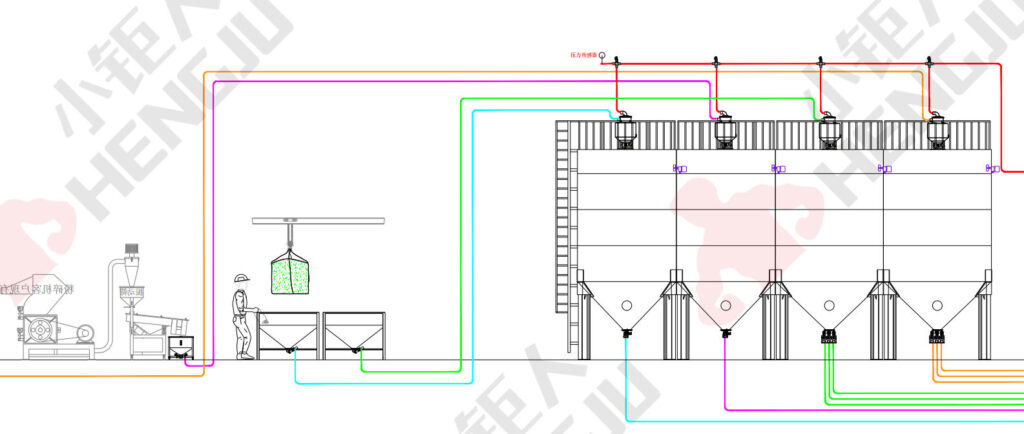

From Bag Unloading to Indoor Silos: Building a Stable Material Foundation

All raw materials enter the system through big bag unloading stations, minimizing manual handling and dust generation. From there, materials are transferred into four indoor silos, designed specifically around the customer’s material structure:

- Two 6 m³ silos for red materials

- One for recycled pellets

- One for directly regrinded material

- Equipped with a single-line vacuum conveying box

- One 6 m³ silo and one 10 m³ silo for white materials

- Separate storage for recycled and regrind materials

- Equipped with a three-line vacuum conveying box

This silo configuration allows the workshop to maintain sufficient buffer storage while keeping material flows clearly separated and easy to manage.

Centralized Conveying and Gravimetric Mixing

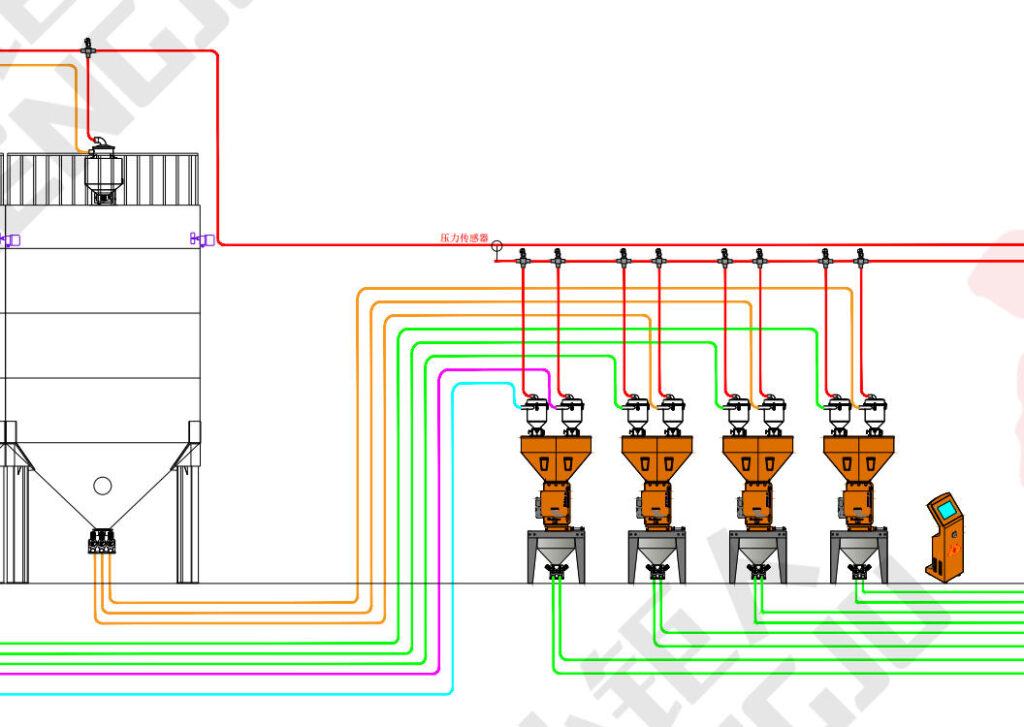

From the silos, materials are conveyed through a central feeding system to four gravimetric blenders, each configured for two-component weighing and mixing.

By centralizing conveying and dosing:

- Each production line receives consistent material ratios

- Manual material transport between machines is eliminated

- Color consistency and material stability are maintained across all shifts

Once accurately weighed and mixed, materials are delivered directly to the injection molding machines, ensuring continuous and synchronized operation across all 82 units.

How the Central Feeding System Improved Workshop Operation

Rather than focusing only on automation, the system was designed to support real-world production conditions:

- Continuous high-load operation exceeding 3.4 tons/hour

- Multiple materials running simultaneously

- Minimal operator intervention during daily production

- Clear material flow paths, reducing the risk of cross-contamination

The result is a workshop where material handling no longer limits production capacity. Operators can focus on machine operation and quality control, while material supply remains stable, clean, and predictable.

Why Central Feeding Systems Are Ideal for Pipe Fittings Manufacturers

Pipe fittings injection molding plants typically operate at high volumes with limited tolerance for downtime. This case demonstrates how a well-designed central feeding system supports:

- Large-scale, multi-line production

- Mixed use of virgin and recycled materials

- Stable feeding for dozens of injection molding machines

- Cleaner, safer, and more organized workshops

For manufacturers producing PVC or PPR pipe fittings, centralized material handling is no longer just an upgrade—it becomes a foundation for scalable and efficient production.

Explore how a central feeding system for injection molding works and how it can be applied to large-scale production workshops like this one.

Ready to upgrade your material feeding system?

✉Request a Free Layout Plan

📋 Download Technical Brochure

Contact now

Email: Jenny@gdhengju.com