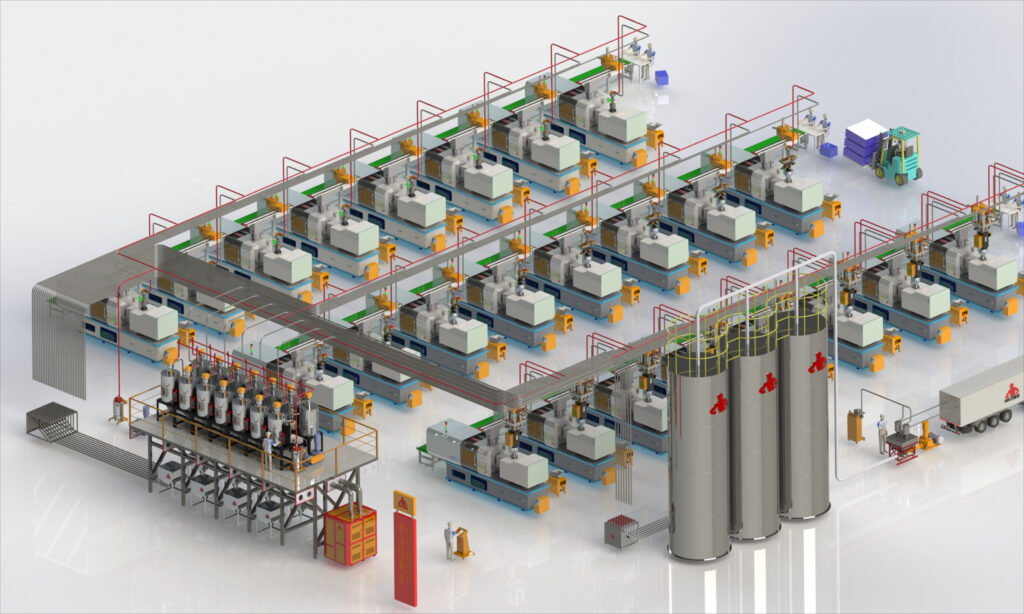

The Central feeding system is designed for the production of plastic products in the injection molding workshop, realizing uninterrupted unmanned continuous molding operations.

automation, intelligence

The storage and feeding system is fully automatic control to complete the feeding action to the plastic auxiliary molding equipment. The central console controls the feeding of multiple molding equipment, and can also monitor the working status and possible failures of the system in real time.

Digitalization of the production process

Visualization of production data such as material usage, product yield rate, and equipment startup status is clear at a glance, and the system is simple, easy to understand, and easy to operate.

centralized management

Automated production realizes the centralized transportation management of raw materials, and uses digital precision control to reduce material loss and labor waste. At the same time, it also reduces the noise and pollution generated in the production process, so as to maintain a clean workshop and enhance the corporate image.

Intelligent transportation

How to free up factory space and reduce transportation costs. We solve the problem from the source, adopt the packaging method of automatic unpacking machine, raw material suppliers provide bulk materials, and adopt the method of container unloading. Bulk materials are cheaper than packaging materials, and companies that use large quantities can save more than one million dollars a year by using bulk materials.

Flexible design, long service life

According to the needs of customers, we can provide personalized central feeding schemes. Different workshop characteristics and different raw material usage requirements can design optimal solutions according to actual needs to meet and optimize the production process of customers.

We, Hengju Machinery, actively responded to the country’s policy of vigorously supporting the upgrading and transformation of plastics enterprises. For plastics production enterprises, we launched the “Enabling 100 Enterprises” plan for the digitalization, intelligence, and unmanned operation of the plastics manufacturing industry. 1,000 plastic production enterprises quickly completed the digital, intelligent, and unmanned upgrading and transformation of production workshops.

Hengju Machinery can provide you with the design scheme of the whole factory automation intelligent factory and the planning and design scheme of water and electricity. We have 10 years of industry experience and 8,000 square meters of self-built factory buildings, tailor-made solutions, free design renderings.