Plastic products are widely used in our daily life and social production. However, a large number of disposable plastic products cause environmental pollution and cannot be degraded and digested by the ecosystem. It is imminent to solve the problem of plastic pollution, and the replacement of biodegradable plastics is one of the important ways to solve the problem.

How big is the biodegradable plastic industry market?

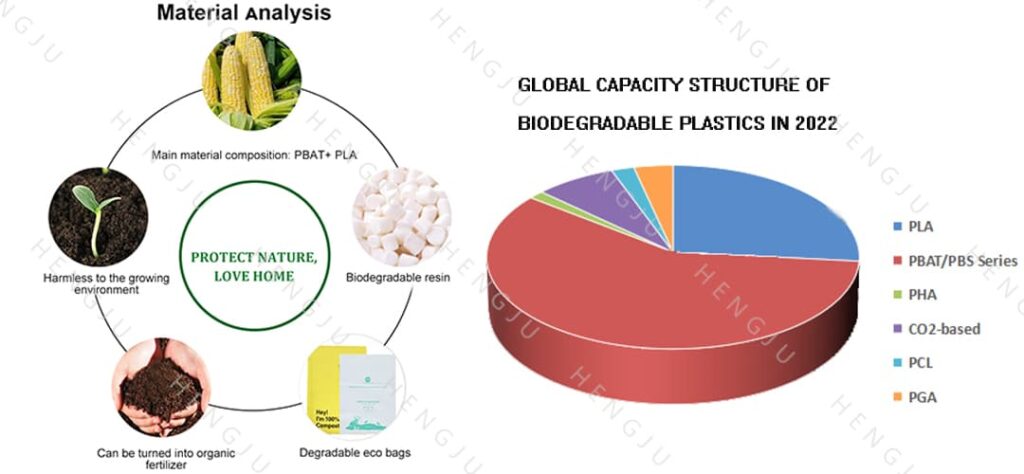

At present, the main degradable plastics mainly include PLA, PBAT, PHA and other products. Biodegradable plastics are the latest degradable plastics, which are characterized in that their base materials can be completely decomposed under the action of microorganisms in nature.

From the perspective of degradable plastic products, PLA and PBAT are currently the mainstream biodegradable materials on the market. In the past three years, starch-based plastics have accounted for as high as 38%, with a large amount of use, followed by PBAT (25%) and PLA (24%).

The global plastic production is nearly 400 million tons, and the biodegradable plastics industry only accounts for 1.227 million tons of plastics in the world, accounting for only 0.3% of the total plastics. The biodegradable plastics industry has a huge development prospect.

Driven by the pressure of plastic pollution and the “plastic limit” and “dual carbon” policies, the replacement rate of degradable plastics is increasing year by year. At present, there is a huge space gap in the degradable plastic market, which is a typical “blue ocean” market.

Why do biodegradable plastics account for so little in the plastics market?

As an environmentally friendly plastic, biodegradable plastics have received more and more attention and attention in recent years, but there are still some problems in practical applications.

1. The technology is not mature enough and the cost is high

biodegradable plastics need to be degraded for a long time, and the degradation speed is not ideal. Certain harmful substances will also be produced during the degradation process. The production technology still needs further research and development. The current production cost of biodegradable plastics is still high, and the production efficiency needs to be improved.

2. The scope of application is limited

The scope of application of biodegradable plastics is mainly concentrated in daily necessities such as disposable tableware and shopping bags, as well as specific fields such as agriculture and medical treatment. In some high-end applications, the performance of biodegradable plastics cannot meet the requirements.

3. High competitive pressure

At present, traditional plastics occupy a dominant position in the plastics industry. Compared with traditional plastics, biodegradable plastics have higher prices and greater competitive pressure.

4. Consumer awareness and acceptance

There is no corresponding standard for production supervision, which leads consumers to have doubts about the performance and quality of biodegradable plastics, such as their strength, stability, and durability.

Central Conveying system + biodegradable materials to realize the green transformation of plastic manufacturing!

A modified plastics company, a leading new material company in Asia Pacific and the world. Independent research and development covers modified plastics, environmentally friendly high-performance recycled plastics, fully biodegradable plastics and other products, with an annual production capacity of 800,000 tons of modified plastics. The introduction of the central conveying system this time solves the problems of front-end compounding and back-end dehumidification and drying during the production of granulation. The central feeding system + biodegradable materials realizes the green transformation of plastic manufacturing!

1. Raw material weighing and dosing system

The customer produces degradable plastic raw materials, which use plant starch as the base material. When mixing raw materials in the early stage of production and manufacturing, the gravimetric blender equipment is used for raw material proportioning. The proportioning accuracy error is controlled within 0.05%, which is better than the original Manual batching can save 15% of raw material waste and increase the speed of mixing by 30%. The gravimetric blender has more than 50 groups of formula storage functions. When in use, hierarchical management passwords can be set to keep the formula confidential, and it can support the output of statistics on the amount of raw materials used later.

2. Dehumidifier and drying system

When preparing granules, it is usually necessary to dry the raw materials, because moisture will affect many aspects of the shape, size, distribution and properties of the granules. Dehumidifier and drying can improve the quality and stability of granules, reduce costs and energy consumption, improve production efficiency and quality, and at the same time protect equipment.

The air pipeline of the dehumidifier and drying system adopts a closed circulation system and is equipped with a filter, so it is not affected by the external climate. Ensure the stability of product quality and reduce the scrap rate caused by humidity problems. The thermal insulation drying barrel is designed with a high-efficiency down-blowing diffuser, and the cyclone exhaust device greatly improves the drying efficiency, prevents heat loss, and improves production efficiency. At the same time, it can purify the air and improve the production environment.

Since the raw material contains starch and has a certain viscosity, it is designed to add stirring during drying, which can improve the drying efficiency, avoid particle agglomeration, and avoid affecting the drying effect. Improve pellet quality, reduce energy consumption, and facilitate operation. Compared with traditional dehumidifier and drying, it can reduce the drying time by 30%, the regeneration temperature by 20%, and the power by 30%, saving energy and reducing costs.