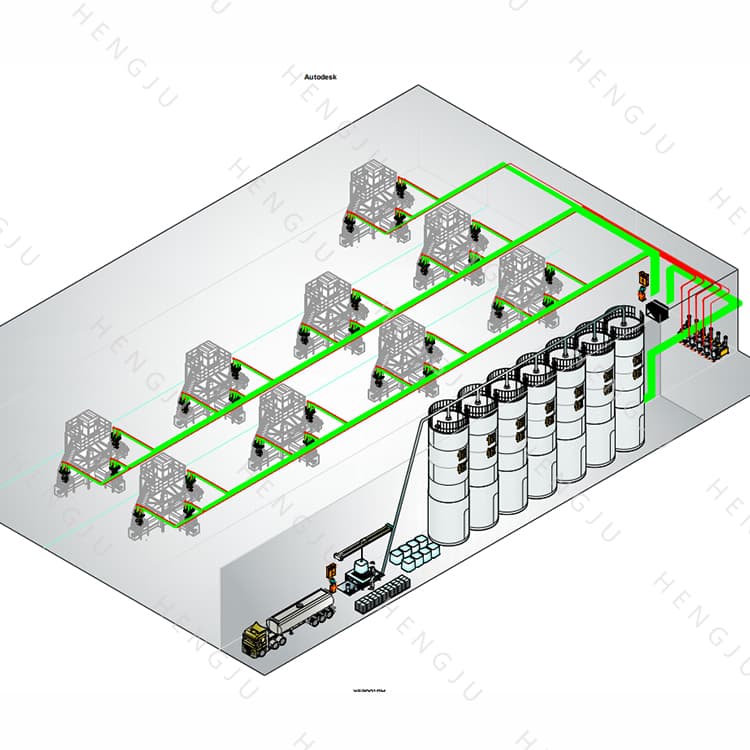

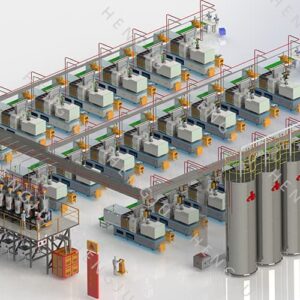

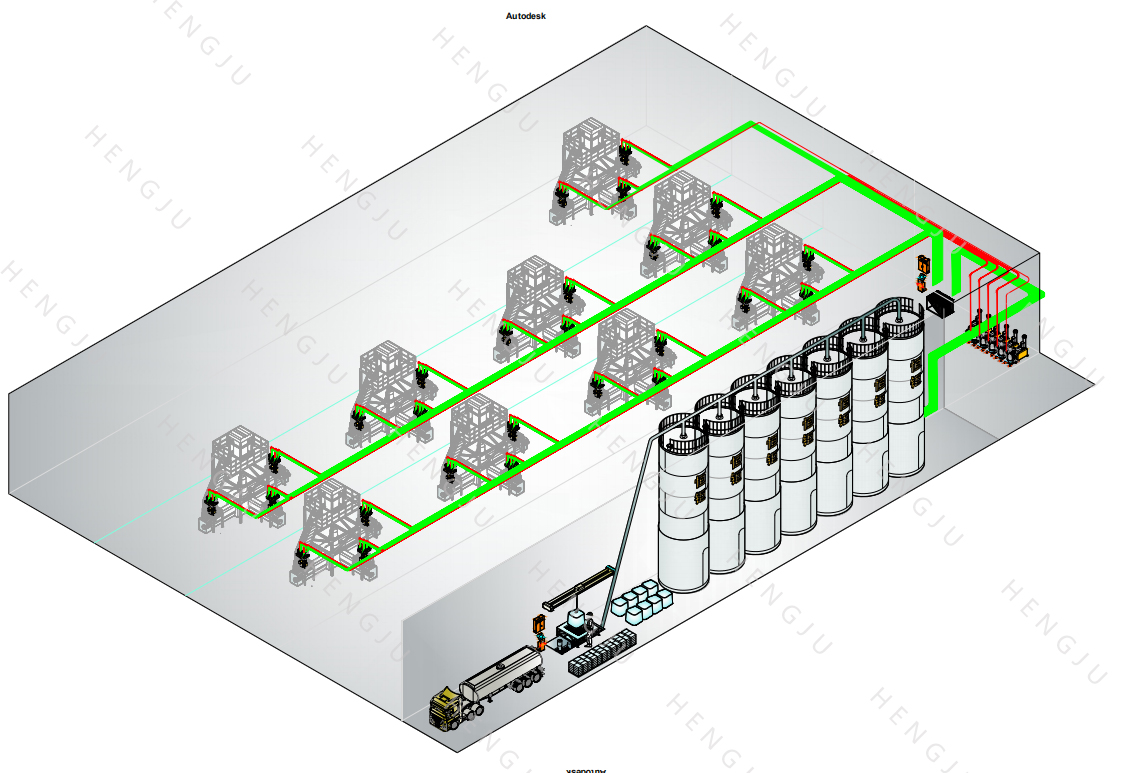

Central Conveying System Introduction:

Centralized control operation and delivery of raw materials through the central control station, including the whole process of raw material unpacking and unloading, storage, transportation, intelligent formula, machine batching, etc. The central feeding system has integrated functions of system protection, centralized monitoring, remote operation, and optimized operation.

material handling systems advantage:

More than 50% energy saving.

Save more than 60% of labor.

Improve production efficiency by more than 30%.

Keep the production workshop clean and tidy, and enhance the corporate image.

Centralized control equipment conveys raw materials and precise ingredients.

Application fields:

Blown film workshop

System Components:

1. Central Control Station:

Centralized control of the entire system, intelligent PLC + touch screen, easy to operate.

2. Roots blower:

The fan that sends air to the whole system makes the raw materials reach the silo or injection molding machine faster;

3. Automatic unpacking and feeding:

Automatic unpacking machine:

It can unpack 400 packages per hour, and can realize batch unpacking operations of 20-50KG.

Raw material storage silo:

Using sealed pipes and positive pressure fans to transport raw materials to outdoor storage bins, centralized management of raw materials improves warehouse utilization by 3-5 times.

4.Weighing and mixing:

gravimetric blender is advanced control algorithm, self-optimization, the precise error of ingredients can reach 0.05%.

It has the functions of formula storage and confidentiality.

5. Dust collector:

Protect the fan and collect fine dust.

6. Material Distribution Station:

Separate the raw material so that the raw material is distributed to each injection molding machine.

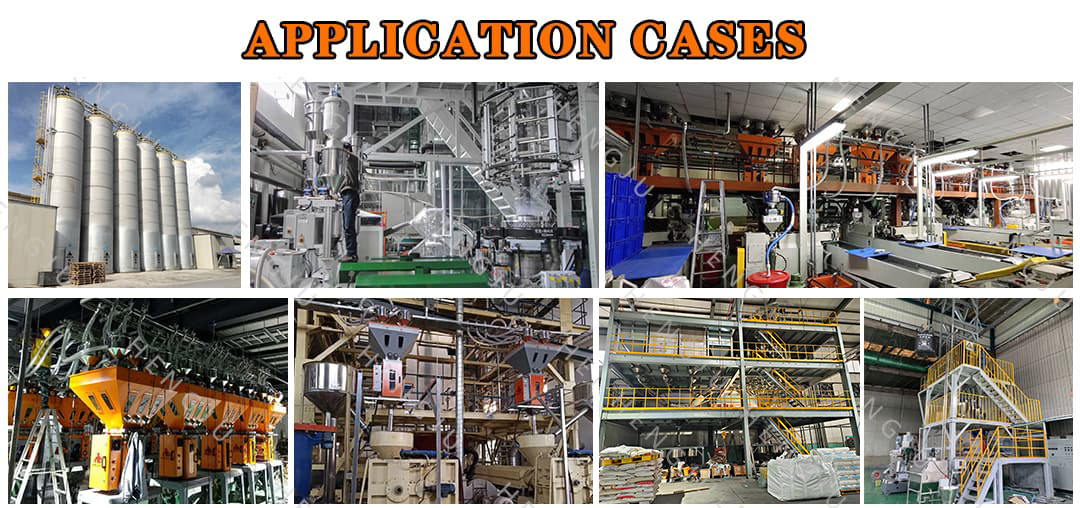

Since its establishment, Hengju has been focusing on the research and development of dehumidifying & drying, dosing & mixing and central conveying systems to make products closer to customer’s demand and customize complete automation solutions for customers.

Hengju Machinery can provide you with complete plant automation solutions and central chiller plant design. We have 15 years of industry experience and 8,000 square meters of self-built workshops, providing services for hundreds of companies, tailor-made solutions, free design renderings, and 24-hour online communication services.

Relying on strong professional technology and stable quality, we have won high comments from customers at home and abroad. Covering industries include auto parts, chemical industry, pelletizing, new energy, new materials, etc., and excellent performance in bio-degradable plastics such as PLA, PBAT, and pipe/sheet/cable extrusion and other fields!