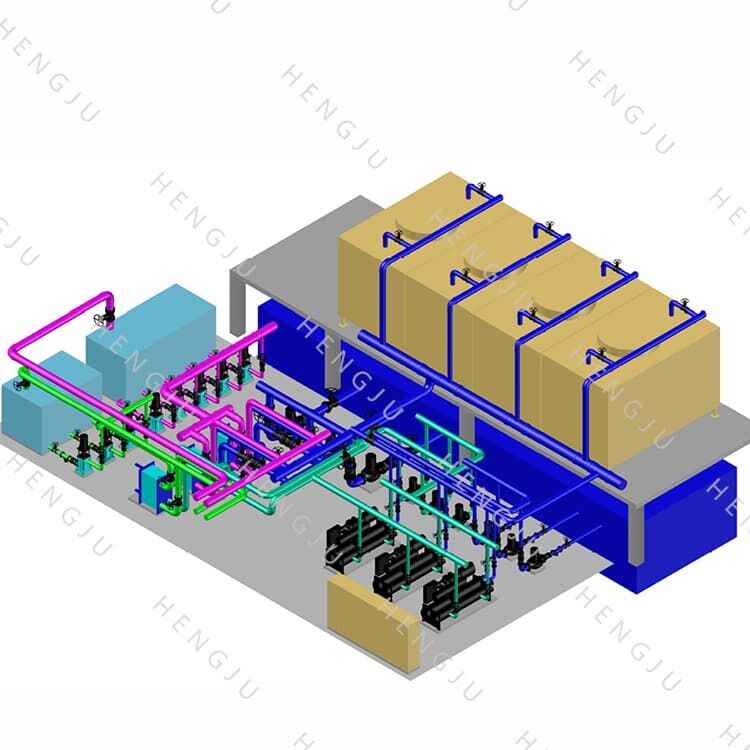

Central chiller system are an essential part of any large-scale industrial cooling operation. These systems are designed to provide chilled water to various parts of an industrial facility, including process cooling, air conditioning, and other applications that require a significant amount of cooling. A central industrial cooling system is typically made up of a network of pipes, pumps, chillers, and cooling towers that work together to provide a consistent supply of chilled water. The design of a central chiller plant is crucial to ensure optimal efficiency and reliability, as well as to meet the specific cooling needs of the facility. Proper planning and design of the central chiller plant can result in significant cost savings and improved operational performance.

Since its establishment, Hengju has been focusing on the research and development of dehumidifying & drying, dosing & mixing and central conveying systems to make products closer to customer’s demand and customize complete automation solutions for customers.

Hengju Machinery can provide you with complete plant automation solutions and central chiller plant design. We have 15 years of industry experience and 8,000 square meters of self-built workshops, providing services for hundreds of companies, tailor-made solutions, free design renderings, and 24-hour online communication services.

Relying on strong professional technology and stable quality, we have won high comments from customers at home and abroad. Covering industries include auto parts, chemical industry, pelletizing, new energy, new materials, etc., and excellent performance in bio-degradable plastics such as PLA, PBAT, and pipe/sheet/cable extrusion and other fields!