In the automotive manufacturing industry, the injection molding process is the core link in the production of plastic parts inside and outside the car. However, with the growth of market demand and the increase of product complexity, the problem of feeding management in the injection molding process has become more prominent. How to ensure the stable supply of raw materials, reduce the errors caused by manual operation, and cope with the production needs of multiple varieties have become severe challenges facing enterprises. In order to meet these challenges, more and more companies have begun to adopt central feeding systems to improve production efficiency and product quality.

Feeding Challenges in Injection Molding

In traditional injection molding production lines, raw material supply usually relies on manual operation. Due to the different experience levels of workers, the accuracy of feeding is often difficult to guarantee, which easily leads to unstable product quality. In addition, with the increase in the variety of automotive parts, companies often need to replace materials, which further increases the complexity of feeding management. If the feeding system cannot respond quickly, it will not only affect production efficiency, but also may lead to material waste and rising production costs.

In this context, companies need a smarter and more efficient feeding solution to ensure the stability and efficiency of the production process. The central feeding system came into being under this demand.

Working principle and advantages of the central feeding system

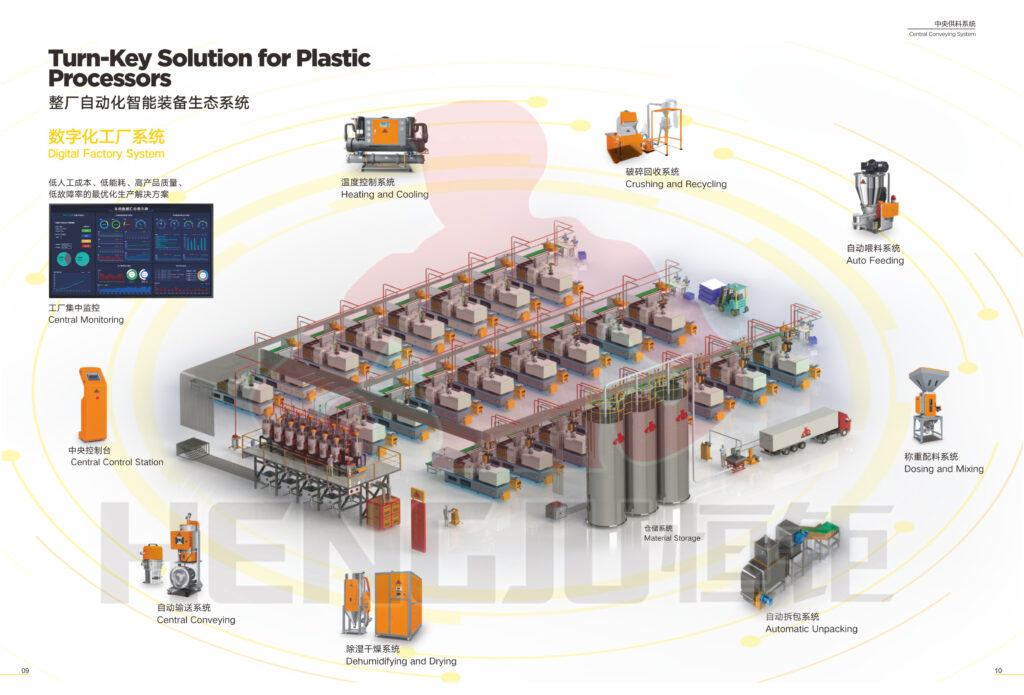

The central feeding system is an integrated raw material delivery and management system that delivers the centrally stored raw materials to each injection molding machine through pipelines. The system can realize the automatic delivery, precise metering and centralized control of raw materials, significantly improving the stability and efficiency of the feeding process.

- Accurate feeding to ensure product quality

The central feeding system monitors the supply of raw materials in real time through precise metering equipment and sensors to ensure that each injection molding machine can obtain a stable supply of raw materials. This highly automated feeding method effectively avoids the problems of uneven feeding and unstable quality caused by human operation, so that the plastic parts produced can maintain consistent high quality in each batch.

- Automated management to improve production efficiency

Faced with the production needs of multiple varieties and batches, the central feeding system can quickly adjust the feeding parameters, automatically complete the material switching, and reduce the downtime of the production line. For example, when producing parts of different colors or materials, the system can quickly empty the residual raw materials in the conveying pipeline and start new material delivery, greatly improving production efficiency.

- Save costs and reduce waste

The central feeding system has a high degree of automation, which greatly reduces the dependence on manual labor and reduces labor costs. At the same time, because the system can accurately control the supply of raw materials, it avoids waste caused by overfeeding. In addition, the central feeding system can also reduce the risk of contamination of raw materials during transportation and improve the cleanliness and environmental protection of the production line.

- Improve the level of enterprise intelligence

The application of the central feeding system is not only an improvement in production efficiency, but also an important step for enterprises to transform to intelligent manufacturing. Through integration with the production management system, the central feeding system can collect and analyze production data in real time to provide a basis for the company’s decision-making. At the same time, the system’s intelligent monitoring and early warning functions can also help companies to promptly discover and solve potential production problems, further improving production reliability.

Practical application of central feeding system in automotive injection molding

The application of central feeding system in automotive injection molding has been widely recognized. For example, in the production of key components such as automotive dashboards, bumpers, and headlight housings, stable supply and precise control of raw materials are essential. Through the central feeding system, companies can effectively guarantee the production quality of these key components while significantly improving production efficiency.