With the intensification of global manufacturing competition, companies in the injection molding industry are facing unprecedented pressure. How to improve production efficiency while ensuring product quality and reducing production costs has become the core goal of enterprise development. In this process, the optimization of the feeding link is crucial. The traditional manual feeding method can no longer meet the needs of modern production. Therefore, more and more companies are beginning to adopt intelligent central feeding systems to comprehensively improve the automation level of the workshop.

Limitations of manual feeding and challenges of production efficiency

In injection molding production, feeding is a basic but extremely important link. Although manual feeding is simple and easy, it exposes the following key problems in large-scale production:

1.High labor costs and low efficiency

In traditional injection molding workshops, manual feeding requires special personnel to operate, which not only increases labor costs, but may also lead to low feeding efficiency due to negligence or fatigue of operators. As the scale of the workshop expands, the limitations of manual feeding become more and more obvious.

2.Unstable feeding and difficult to guarantee quality

The accuracy of manual feeding cannot be compared with that of automated equipment. In the production process that requires precise batching, manual operation is prone to errors, resulting in inconsistent product quality, and may even lead to batch product failure, thus causing economic losses to the company.

3.Frequent interruptions to production and increased equipment loss

Manual feeding often requires frequent downtime for refilling, which not only reduces production efficiency, but also may cause excessive wear of equipment due to frequent equipment start and stop, increasing maintenance costs.

4.Safety hazards are difficult to ignore

During the feeding process, workers need to carry heavy objects, especially in high temperature environments, which are prone to safety accidents. This not only affects the health and safety of workers, but also brings challenges to the company’s safe production management.

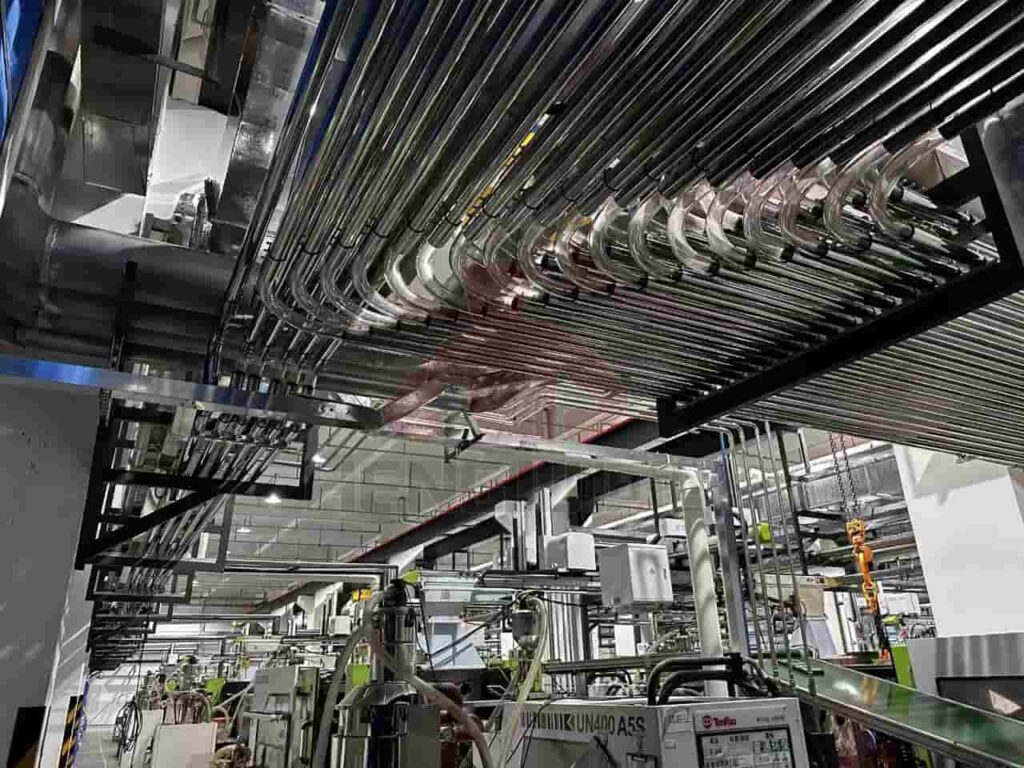

The emergence of intelligent central feeding system: the best solution to the feeding problem

In the face of the above challenges, the intelligent central feeding system has become the best solution for the feeding link of the injection molding workshop with its characteristics of automation, precision and efficiency. Its application not only improves production efficiency, but also brings many additional benefits to the company.

1.Automated operation, reducing labor costs

The intelligent central feeding system completely replaces the cumbersome operation of manual feeding through fully automated control. Enterprises no longer need to invest a lot of human resources for feeding operations, saving labor costs, and the stable operation of the automation system greatly improves production efficiency.

2.Accurate feeding to ensure product quality

The system can accurately control the supply of each raw material according to the specific needs of production to ensure uniform mixing and stable supply of materials. Through intelligent control, enterprises can ensure the consistency of product quality in each batch and greatly reduce the production of defective products.

3.Continuous feeding to reduce production interruptions

The large-capacity storage device of the intelligent central feeding system can continuously feed for a long time, avoiding production interruptions caused by frequent feeding. By reducing the number of downtimes, the service life of the equipment is extended and the maintenance cost is reduced accordingly.

4.Improve workshop safety

The automated feeding system greatly reduces the working time of workers in high temperature and high intensity environments and reduces the incidence of work-related accidents. The safety of the workshop has been significantly improved, and the health of workers has been better protected.

Industry practice: Successful case of intelligent central feeding system

After a large plastic products company introduced an intelligent central feeding system, the overall production efficiency of the workshop increased by 40%. By precisely controlling the supply of raw materials, the company not only improved product quality, but also reduced raw material waste and saved a lot of production costs. In addition, the automated operation of the system greatly reduced safety hazards in the production process, making the working environment of the workshop safer and healthier.

Summary

In modern injection molding production, the automation and intelligence of the feeding link are the key to improving production efficiency and ensuring product quality. With its excellent performance and stable operation, the intelligent central feeding system has helped enterprises effectively solve many problems of traditional manual feeding, laying a solid foundation for the long-term development of enterprises. If your company is looking for an efficient and safe feeding solution, the intelligent central feeding system is undoubtedly your best choice.