In modern plastic injection molding, a central feeding system serves as the backbone of material handling, enabling factories to streamline production, improve efficiency, and reduce waste. By integrating advanced auxiliary equipment such as gravimetric blenders, vacuum loaders, and material handling fans, these systems automate the entire material supply chain, ensuring that raw materials are accurately conveyed, mixed, and fed into the injection molding machines.

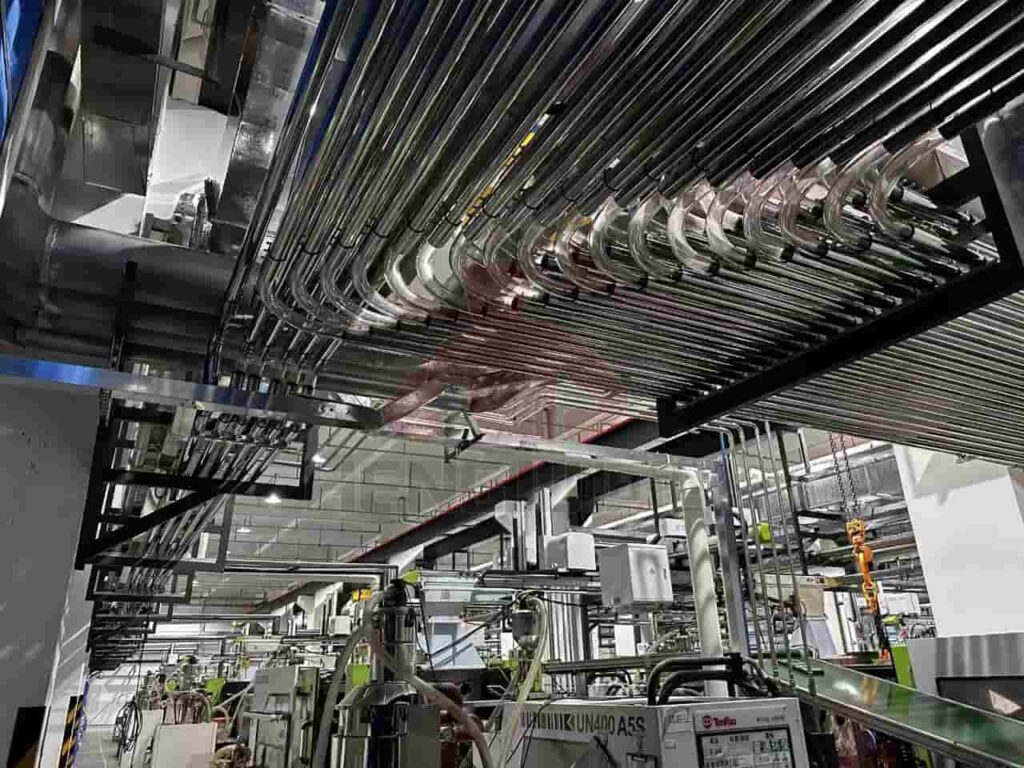

The process begins when raw plastic materials, typically delivered in bulk bags or containers, are automatically unpacked. After unpacking, the materials are transported through pneumatic conveyors powered by material handling fans. These fans generate the necessary airflow to move plastic pellets or granules over long distances, depositing them into centralized storage silos. By eliminating manual handling, this system reduces the risk of material contamination and improves safety.

Once the material is stored, the next step involves feeding it into the molding machines. Here, a gravimetric blender plays a crucial role. The blender precisely measures and mixes the materials according to predetermined ratios, ensuring consistency and uniformity in the material blend. This is especially important for molding processes that require specific material properties for high-quality outputs. The gravimetric blender is a key part of the system, as it automatically adjusts to the required material mix, minimizing human error and material waste.

When the material is ready, it is transported to the injection molding machine via vacuum loaders. These devices use suction to transfer the mixed material from the storage silos to the machine hoppers, ensuring that the molding machines receive the right amount of material at the right time. The continuous, automated feeding process eliminates any interruptions in production and allows the machines to operate efficiently without delays caused by material shortages or manual loading.

Another important aspect of a central feeding system is its recycling capabilities. Throughout the production process, scrap or excess material is generated. This waste is not discarded; instead, it is collected and routed back through the system for recycling. Recycling equipment processes the waste material, grinding and reusing it in future production cycles. This closed-loop system helps manufacturers reduce material costs and minimize environmental impact, making the entire production process more sustainable.

The integration of these auxiliary machines within the central feeding system brings numerous benefits to manufacturers. The automated handling of materials reduces the need for manual labor, cutting operational costs while increasing efficiency. The gravimetric blenders ensure that the material mixtures are always accurate, improving product quality and reducing the risk of defects. Additionally, the use of vacuum loaders and recycling systems ensures that the feeding process is continuous and that waste is minimized, contributing to a more sustainable production environment.

Moreover, the central feeding system with auxiliary equipment also optimizes space within the factory. By centralizing material transport and automating key processes, factories can use their floor space more effectively, allowing for higher production volumes without expanding the physical footprint of the facility. This space optimization is particularly valuable for factories looking to scale production without the need for costly new infrastructure.

In summary, the central feeding system is a vital part of modern plastic injection molding operations. When paired with auxiliary equipment like gravimetric blenders, vacuum loaders, and recycling systems, it not only automates material handling and improves efficiency but also contributes to cost savings, consistent product quality, and environmental sustainability. As the manufacturing industry continues to push for higher levels of automation, the importance of these integrated systems will only grow, making them essential for any factory looking to stay competitive in a fast-evolving market.