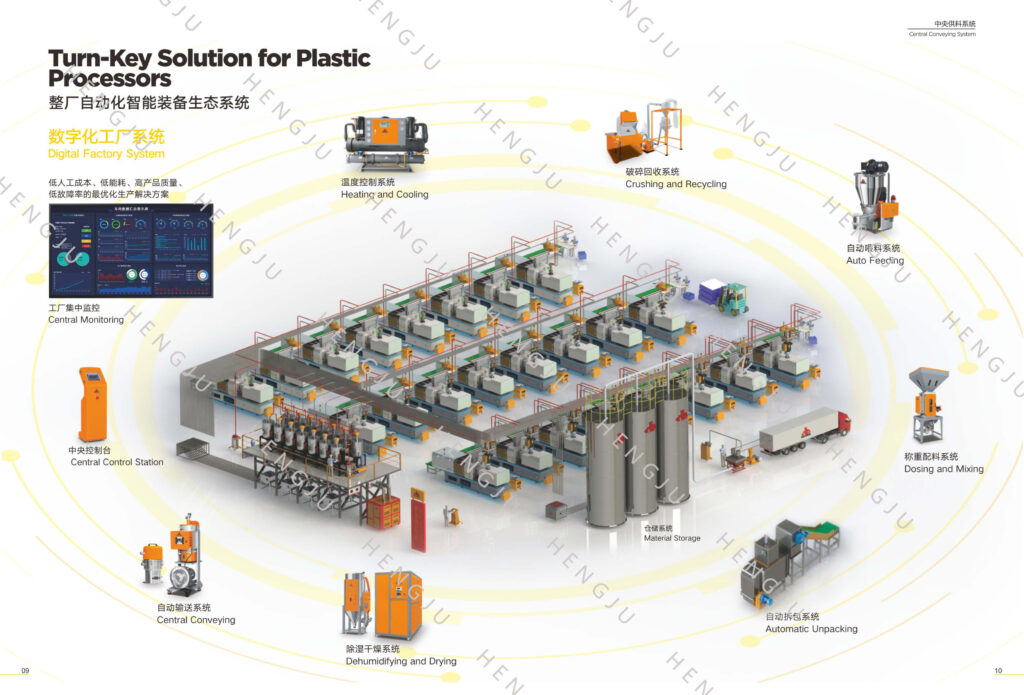

The central conveying system is designed for the production of plastic products in the injection molding workshop, realizing uninterrupted unmanned continuous molding operations. The variety of raw materials and the combined use of multi-color materials can be changed according to the needs, so as to realize the automation of the coloring process. The system can regenerate and use the sprue cold material in a fully automatic manner, and can control all feeding equipment, and prevent the occurrence of blockage in the storage bin, and realize full automation by setting a central monitoring platform

The vaccum conveying system adopts the vacuum conveying method, and transports the plastic raw materials from the storage tank to the central dehumidification and drying system through a centralized pipeline system, and then transports the dried raw materials to each injection molding machine. The central feeding system adopts the design method of “one machine and one pipe” to ensure that the air in the whole system can transport the raw materials and prevent the raw materials from dehumidification and drying from regaining moisture. At the same time, each conveying operation is stable, and there is no phenomenon of material blocking. It is used in conjunction with the central dehumidification and drying system, which can be used to clean the delivery pipeline after the dehumidification and drying cycle to ensure that there are no residual pellets in the pipeline. While avoiding the moisture regain of the raw materials, it also ensures the performance of the raw materials added to the injection molding machine. unanimous. Under the action of vacuum negative pressure, the original dust in the raw material will be filtered out through the dust filtration system, which helps to improve the quality of the molded product.

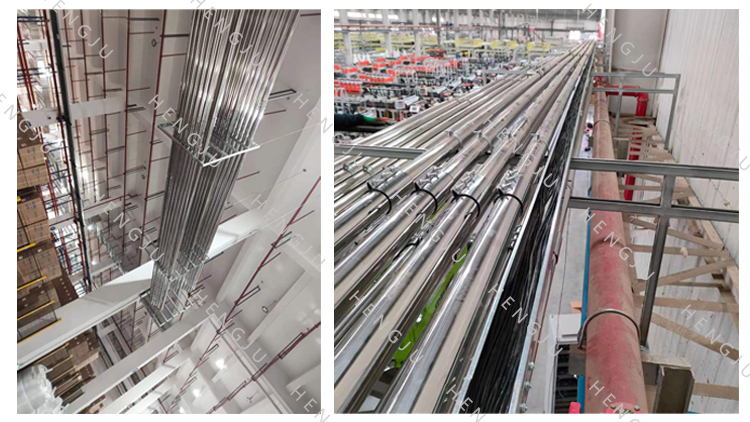

The central vaccum system is composed of most central feeding system accessories. There are very high requirements for the pipeline layout of the central feeding system. The wrong pipeline layout will not only reduce the production efficiency, but also may damage the machine. If you want to change it after the layout is completed, it will be very complicated. Therefore, the pipeline layout of the central feeding system in the early stage is very important. Since the pipeline layout is very important, what are the requirements for the pipeline layout of the central feeding system?

What are the requirements for the pipeline layout of the conveyor system solutions?

1. Under the premise of meeting the conveying requirements, the conveying pipe should shorten the conveying distance as much as possible.

2. The number of bends in the central feeding system should be as small as possible, especially the bends that transition from horizontal to vertical upwards should be used as little as possible.

3. The horizontal pipe should not be too long, otherwise it will easily cause adverse consequences.

4. Consider the rationality of the configuration of the entire production equipment and conveying system to facilitate production.

5. The pipeline installation, inspection and maintenance of the central feeding system should be convenient.

The above are some requirements and matters needing attention of Foshan Xiaojuren Machinery Co., Ltd. for the pipeline layout of the vacuum transfer system for pellets. In order to facilitate a reasonable pipeline layout in the later stage, Foshan Xiaojuren Machinery Co., Ltd. provides free design and free drawing services, and looks forward to your consultation.