In recent years, the injection molding industry has continued to develop, and the growing demand for plastic products in various industries has also increased, thus promoting the development and improvement of the entire plastic molding technology level, and the conveying system has adapted to the requirements for multi-color and multi-variety products. The feeding system has a central conveying system and an automatic feeding system. There are certain differences between the two, and I will explain them to you next.

The difference between the working principle of the central feeding system and the automatic feeding system

The working principle of the vacuum conveying systems is to use the vacuum transmission method, and then transport the plastic raw materials from the storage tank to the central dehumidification and drying system through the centralized pipeline system, and then transport the dried raw materials to each host. It is used in conjunction with the central dehumidification and drying system, which can be used to clean the delivery pipeline after the dehumidification and drying cycle to ensure that there are no residual pellets in the pipeline. While avoiding the moisture regain of the raw materials, it also ensures the consistency of the performance of the raw materials added to the host.

The working principle of the automatic feeding system is to close the vacuum tube, start the motor, send plastic raw materials into the vacuum tube with low-vacuum airflow, stop the motor, and then send the raw materials into the hopper, and so on. In the designed control system, one motor can be used to control two feeding production lines, which are switched by directional valves. The two production lines can run independently or simultaneously. If the two are running at the same time, when one production line is finished conveying, it is judged that the discharge of the other production line has ended, then the motor keeps turning and the direction valve is reversed, so as to feed the other production line. In this way, the efficiency of the control system and the motor can be exerted, so as to realize automatic feeding.

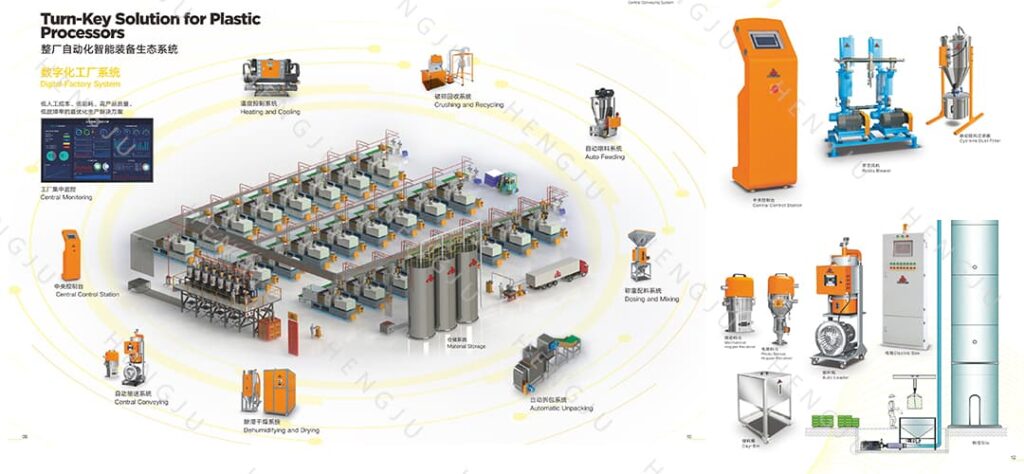

Hengju is an integrated integrator focusing on the R&D and production of plastic molding auxiliary equipment and the design of the whole plant automation system. Years of industry experience has made Hengju always ahead of the same industry in China, and has a broad domestic and foreign markets. With the continuous development and expansion of overseas markets, Hengju’s product sales network has been distributed to dozens of countries in Europe, America, the Middle East, and Asia Pacific. The brand of Hengju is being accepted and recognized by more and more countries.