Introduction

In plastic production, material conveying is more than just moving pellets from point A to point B. The method you choose can significantly impact your plant’s efficiency, cost, and maintenance workload. From small workshops to high-volume injection molding factories, understanding the advantages and limitations of different conveying methods is essential for long-term success.

1. Manual Conveying: Low Tech, High Risk

Manual material handling may seem cost-effective initially, but it introduces many risks: contamination, spillage, inconsistent feeding, and high labor dependence. It’s also difficult to scale as production increases.

Common issues:

- Inconsistent material supply

- Higher contamination risk

- Increased labor cost over time

2. Individual Vacuum Loaders: Simple Automation

Individual vacuum loaders offer a semi-automated approach, suitable for small-scale production. However, they still require multiple units and maintenance for each machine.

Pros:

- Easy to install

- Lower upfront cost

Cons:

- High maintenance due to multiple motors and filters

- Increased noise and energy consumption

- Not ideal for factories with more than 10 machines

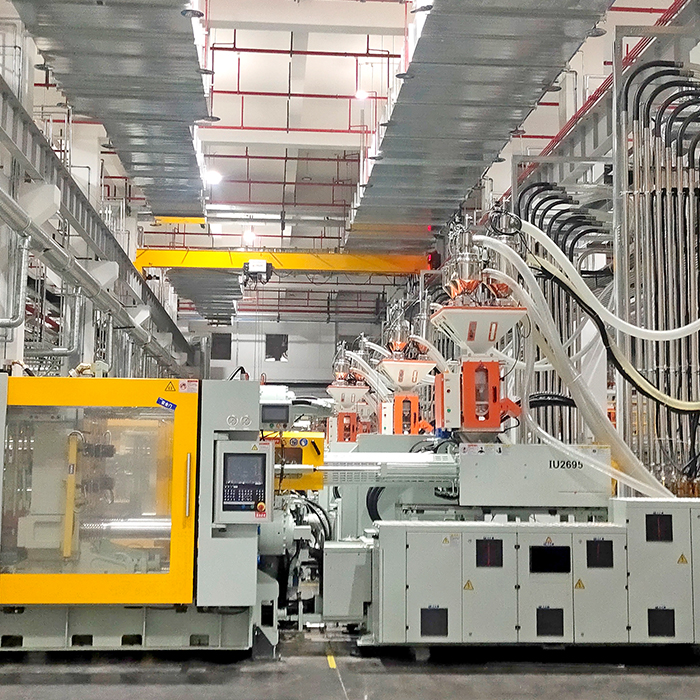

3. Central Conveying System: Scalable & Efficient

A centralized system optimizes material distribution across multiple machines using a single vacuum pump and central control. It reduces energy use, simplifies maintenance, and supports real-time monitoring.

Advantages:

- Uniform material quality

- Reduced equipment redundancy

- Improved workshop cleanliness

- Easier scaling and centralized control

4. Hybrid Setups: The Transitional Option

Some factories use hybrid systems—combining central feeding for major materials with individual loaders for specialty materials. This setup balances cost and performance but may become complex over time.

5. How to Choose the Right Conveying Method

Your ideal solution depends on your production scale, types of plastic materials, cleanliness requirements, and future expansion plans.

Key factors to consider:

- Number of machines

- Material types and throughput

- Desired automation level

- Maintenance capability

Conclusion

Selecting the right material conveying method isn’t just a technical decision—it’s a strategic one. By matching your production needs with the appropriate system, you can improve product quality, reduce downtime, and prepare your plant for future growth.

Ready to upgrade your material feeding system?

✉Request a Free Layout Plan

📋 Download Technical Brochure

Contact now

Email: Jenny@gdhengju.com