With the development of the times, most factories are now phasing out manual labor and favoring intelligent equipment. This is also because the automation equipment can work continuously for 24 hours and accurately control data. Among them, injection molding manufacturers have also used many automation equipment. The volumetric doser is also an injection molding machine. It is an indispensable mechanical equipment for the factory.

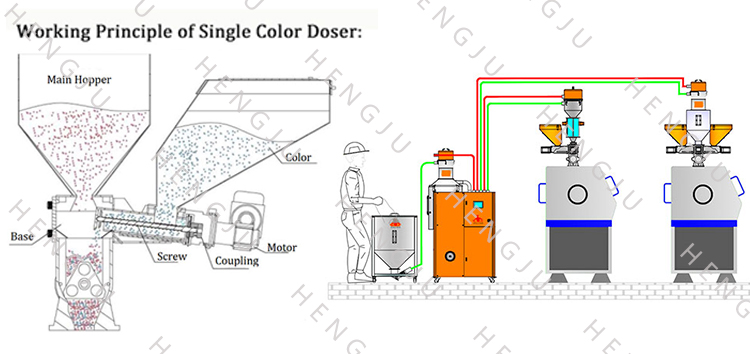

The working principle of volumetric doser:

The signal from the control box is transmitted to the motor, and the motor starts to rotate, which drives the screw to rotate through the coupling. The color masterbatch in the hopper falls into the falling rod, is squeezed by the screw, and is conveyed to the base by the screw to achieve the purpose of metering and conveying the color masterbatch.

The debugging method of the volumetric doser and the test operation process of the volumetric doser:

1. Turn on the secondary power switch behind the control box;

2. Now, press the “Setting” key twice, input the internal parameters of “Job Parameters”, and change the screw number to the corresponding color 01, then change the corresponding number after the screw number to 01 and press the “Setting” key to save . Press the “Stop” key twice to return to the page of ready operation.

3. Press the green button key to display “Arrangement” in the lower left corner of the manipulator text. At this time, the text displayed in the lower left corner of the controller whose rotation speed exceeds 5 rpm changes from “well arranged” to “running”.

4. When the yellow light is flashing, the lower left corner of the text on the controller displays “Running” and changes to “Suspend due to lack of material”, indicating that the material level in the hopper is lower than the detection position, reminding you that you need to add masterbatch.

5. When the red light flashes to control the overload of the thermal relay of the stirring motor, please check whether the current of the thermal relay is too low, or the stirring shaft is wrapped around multiple belts or the motor is short-circuited.

What are the advantages of volumetric doser?

The volumetric doser is suitable for the active proportion mixing of new materials, secondary materials, masterbatches or additives. The motor reduction ratio of this product is 38:1, and the screw diameters are divided into four types: 12, 16, 20, and 30mm. Four models can be evolved to provide different outputs of 0.1-110kg/hr for customers to choose. There is also a double screw volumetric doser, which can be combined with any two color doser machines according to customer needs. If the customer uses a three-pot volumetric doser, four-component active proportion mixing can be realized. It can reduce labor costs and precisely control the proportion of mixing.