The “All In One Dehumidifying Dryer” is a device that integrates dehumidification, drying, and conveying functions, widely used in the plastics processing industry. Its operating principle involves several steps to ensure that plastic pellets are thoroughly dried and treated before processing, thereby enhancing production efficiency and product quality. Here is a detailed explanation of its operation principle:

All In One Dehumidifying Dryer Operating Principle

- Feeding System:

- Raw Material Storage Bin: Plastic pellets are first stored in a raw material storage bin, ready for dehumidification and drying.

- Conveying System: The plastic pellets are transported from the storage bin to the drying bin through a vacuum or mechanical conveying system.

- Dehumidification System:

- Dry Air Circulation: The device features a dry air circulation system. Air first passes through a desiccant wheel or desiccant tower to remove moisture, generating dry air.

- Heater: The dry air is then heated to a set temperature by a heater to improve drying efficiency.

- Drying System:

- Drying Bin: Plastic pellets are fed into the drying bin where they come into contact with hot, dry air. The dry air passes through the pellet bed, removing moisture from the surface and inside the pellets.

- Moisture Exhaust: The moisture-laden air is expelled from the drying bin, where moisture is removed through condensation or adsorption, then recirculated back into the drying system.

- Temperature and Humidity Control:

- Temperature and Humidity Sensors: The device is equipped with sensors to monitor the temperature and humidity inside the drying bin in real time.

- Automatic Control System: Based on sensor feedback, the system automatically adjusts the heater and the dry air circulation speed to ensure optimal drying conditions.

- Conveying System:

- Post-Drying Conveying: The dried plastic pellets are transported to the hopper of an injection molding machine, extruder, or other processing equipment.

- Moisture-Proof Design: The conveying system is usually designed to prevent the dried pellets from absorbing moisture again during transportation.

- Automation and Monitoring:

- PLC Control System: The entire dehumidification and drying process is managed automatically by a PLC control system. Users can set and monitor parameters through a touchscreen or computer.

- Alarm System: The device is equipped with a fault and anomaly alarm system. If issues such as high temperature or excessive humidity occur, the system will automatically alert and take protective measures.

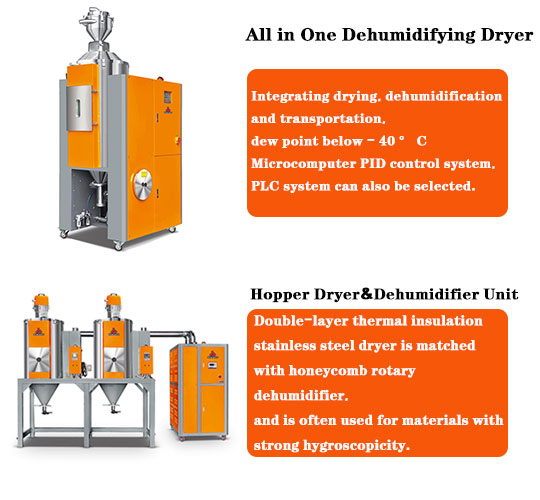

All In One Dehumidifying Dryer Key Features

- High-Efficiency Dehumidification: Utilizes efficient desiccants and a circulation system to quickly remove moisture from plastic pellets.

- Automated Control: The PLC automated control system enhances operational convenience and drying process stability.

- Energy Efficiency: Optimized air circulation and heat recovery systems reduce energy consumption.

- Multi-Functional Integration: Integrates dehumidification, drying, and conveying, simplifying equipment configuration and operation.

Application Scenarios

- Injection Molding: Ensures the plastic pellets are dried before injection molding, preventing defects like bubbles and surface blemishes.

- Extrusion Molding: Dries plastic pellets before extrusion, improving the mechanical properties and appearance quality of the products.

- Blow Molding: Treats plastic for blow molding to enhance product transparency and strength.

Through these principles and features, the All In One Dehumidifying Dryer plays a crucial role in the plastics processing industry, ensuring efficient production and high-quality products.