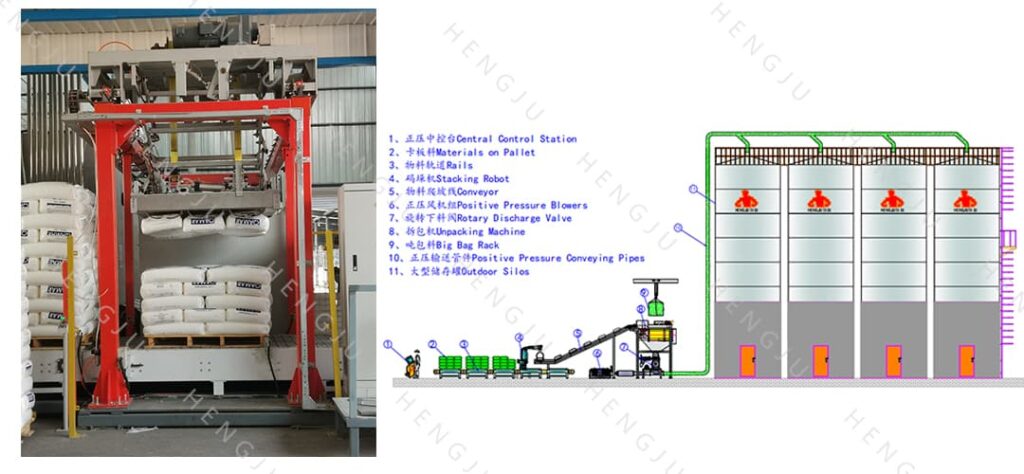

Before the film is formed, the packaging and unpacking procedures in production are important for productivity, dust pollution, and workers’ health. It will spend too much labor cost when you are weighing, measuring, and feeding the raw material. It’s low efficiency to unpack the material bag manually, and the powder is likely to pollute the working environment and endanger workers’ health when you are unpacking, which seems not feasible.

The big bag unloading machine with highly and automatically operation capability, which is suitable in various industries, no matter drying pellet material or small chunks material. This systematic machine is going to replace the traditional way of unpacking manually.

How automatic unpacking machine works?

Automatic unpacking can put the whole pallet of materials into the depalletizing platform. The bulk bag unloader will grab the whole layer of bags through the mechanical hook gradually. During the movement, a row of knife will cut the material packaging bags, and the materials will fall into the storage hopper. The braided yarn will be screen out through the filter box in the last process.

Advantages of automatic unpacking machine

1. The capability of automatic unpacking machine has increased from 30 packs per hour by human to 400 packs per hour, which can realize batch unpacking operations from 20kg/h to 25kg/h. So it can save much cost and improve production efficiency in the meanwhile.

2. Reduce material and energy consumption, good sealing performance, avoid dust leakage, and improve working environment.

3. Using wireless touch screen control, there are multiple working modes, working speeds and bag thicknesses to choose from, making the operation faster and more convenient.

4. The automatic unpacking machine is used together with other conveying equipment after bag breaking, unloading and separation to complete the functions of raw material conveying and storage.

5. The manufacture of equipment can be applied to packaging bags of various specifications, and our automatic unpacking machine can be used for multiple purposes, saving costs.

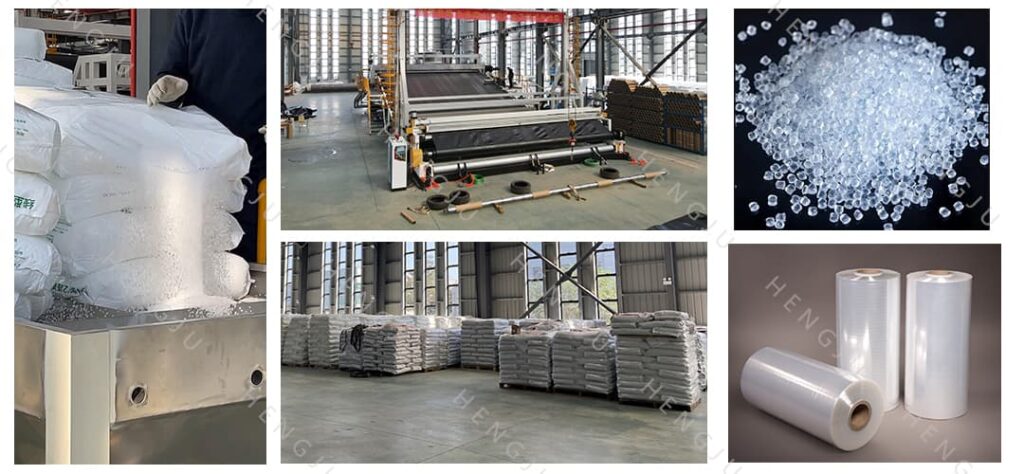

The film industry is the key to improving product quality and building smart factories

Since it found, Hengju has been focusing on the research and development of dehumidifying & drying, dosing & mixing and central conveying systems to make products closer to customer’s demand and customize complete automation solutions for customers. It has provided stable and reliable intelligent systems for thousands of plastic manufacturers.

Gravimetric blender system

The dried raw materials are sent to the gravimetric mixer for batching and mixing. The Gravimetric Blender and the volumetric Color Doser of the dosing and mixing system can measure the main material, color masterbatch, additives or recycled materials of plastic raw materials in proportion Automatic mixing.

Outdoor Silos for Material Storage

Traditional warehousing is limited by the handling method and convenience of operation. Raw material bags cannot be stacked too high, resulting in a large area for raw material storage. For the storage of raw materials, we can provide large silos suitable for outdoor storage At the same time, small storage silo placed on the indoor workshop site can also be provided to store raw materials.