1. Introduction

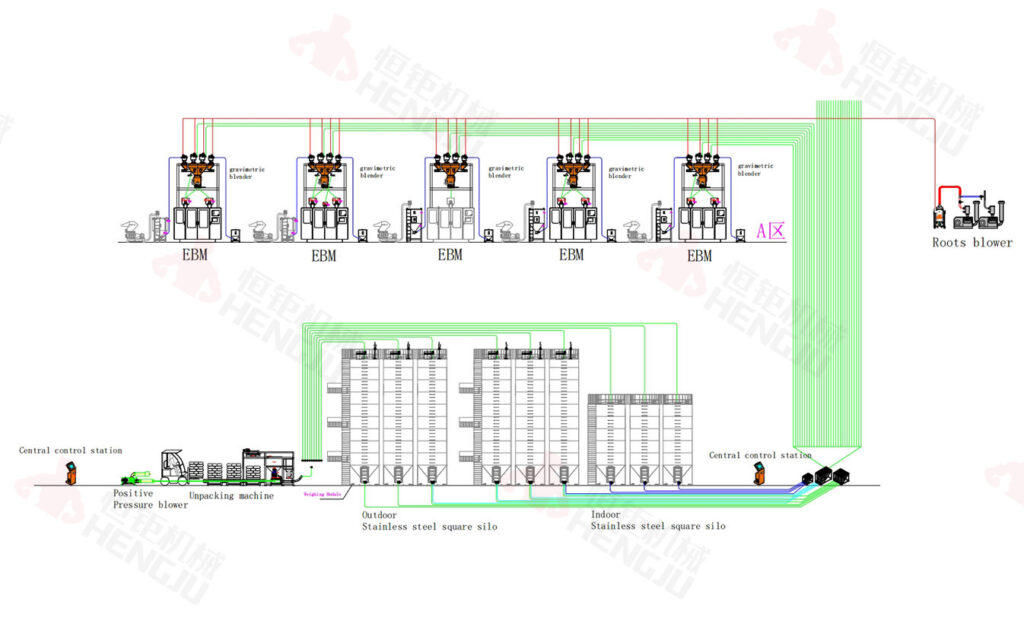

Blow molding factories often face challenges like inconsistent material supply, high labor costs, and dust contamination. A central feeding system for blow molding solves these problems by delivering raw materials directly from storage silos to each blow molding machine automatically.

2. How a Central Feeding System Works in Blow Molding

- Material Storage – Pellets are stored in large silos or bins.

- Vacuum Conveying – Central pumps transport material through sealed pipelines.

- Distribution Manifold – Directs the right material to each blow molding machine.

- Drying & Mixing – Integrated dryers and mixers prepare materials before molding.

3. Benefits for Blow Molding Production

- Continuous Operation – No manual material loading, reducing downtime.

- Material Consistency – Prevents contamination and moisture absorption.

- Lower Labor Costs – Fewer operators needed for material handling.

- Clean Production Environment – No pellet spillage or dust pollution.

- Energy Savings – Centralized drying is more efficient than individual dryers.

4. Key Design Considerations

- Production Scale – Number of machines and daily output.

- Material Type – PET, HDPE, PP, etc.

- Distance & Layout – Pipe length, bends, and floor plan.

- Automation Level – Whether to include gravimetric dosing or drying.

5. Cost Factors

- Initial Investment – Includes vacuum pumps, pipes, receivers, and control system.

- Operating Cost – Energy consumption and filter maintenance.

- ROI Timeline – Many blow molding factories recover costs within 12–18 months.

6. Conclusion

For blow molding manufacturers aiming to improve efficiency and product quality, investing in a central feeding system is a cost-effective solution. The right system reduces waste, saves labor, and ensures consistent material flow — all critical for staying competitive in today’s market.

Ready to upgrade your material feeding system?

✉Request a Free Layout Plan

📋 Download Technical Brochure

Contact now

Email: Jenny@gdhengju.com